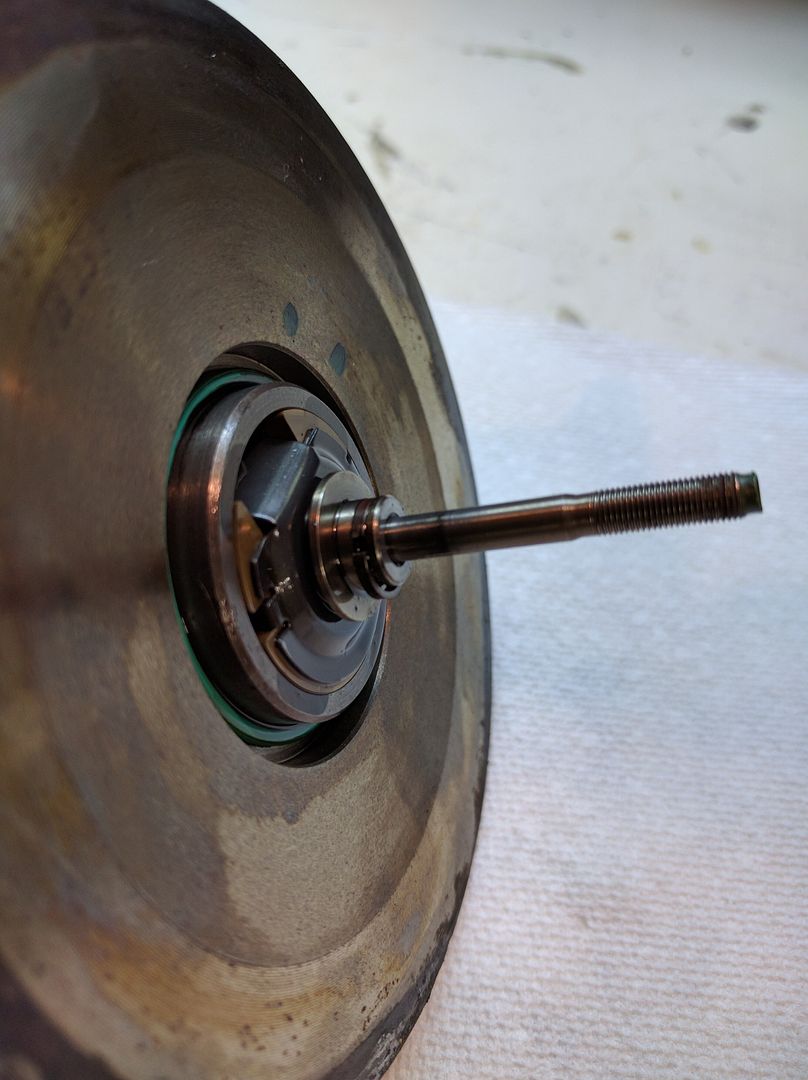

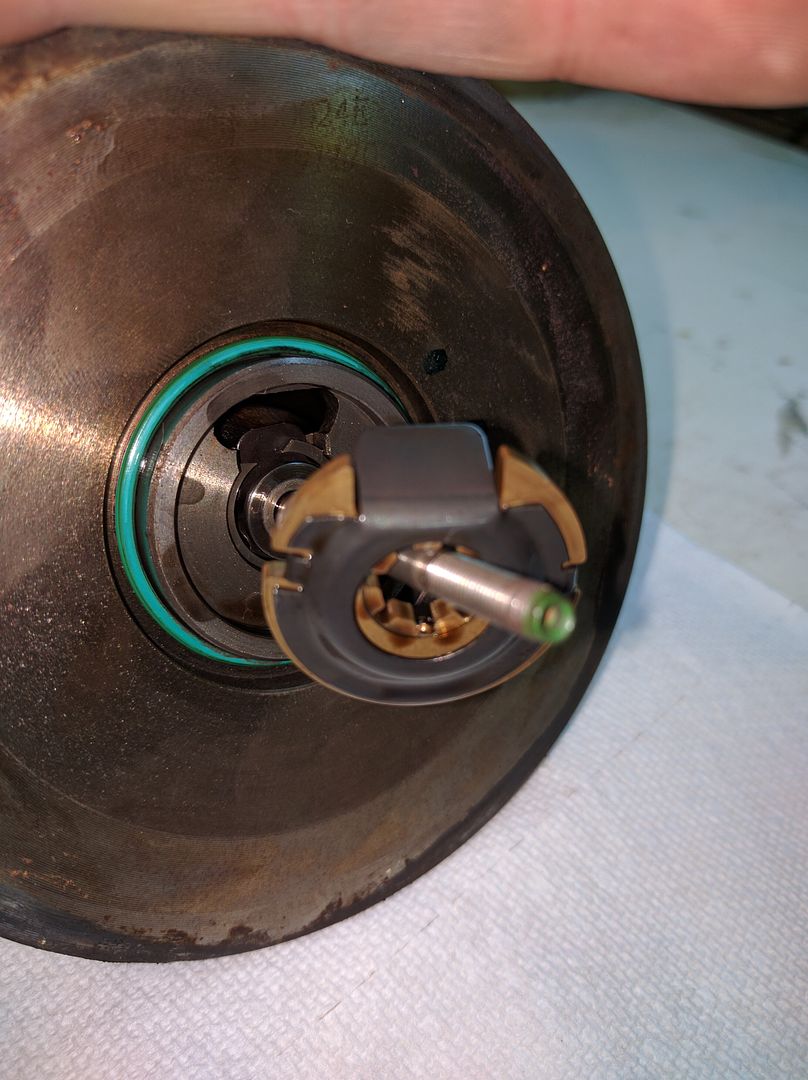

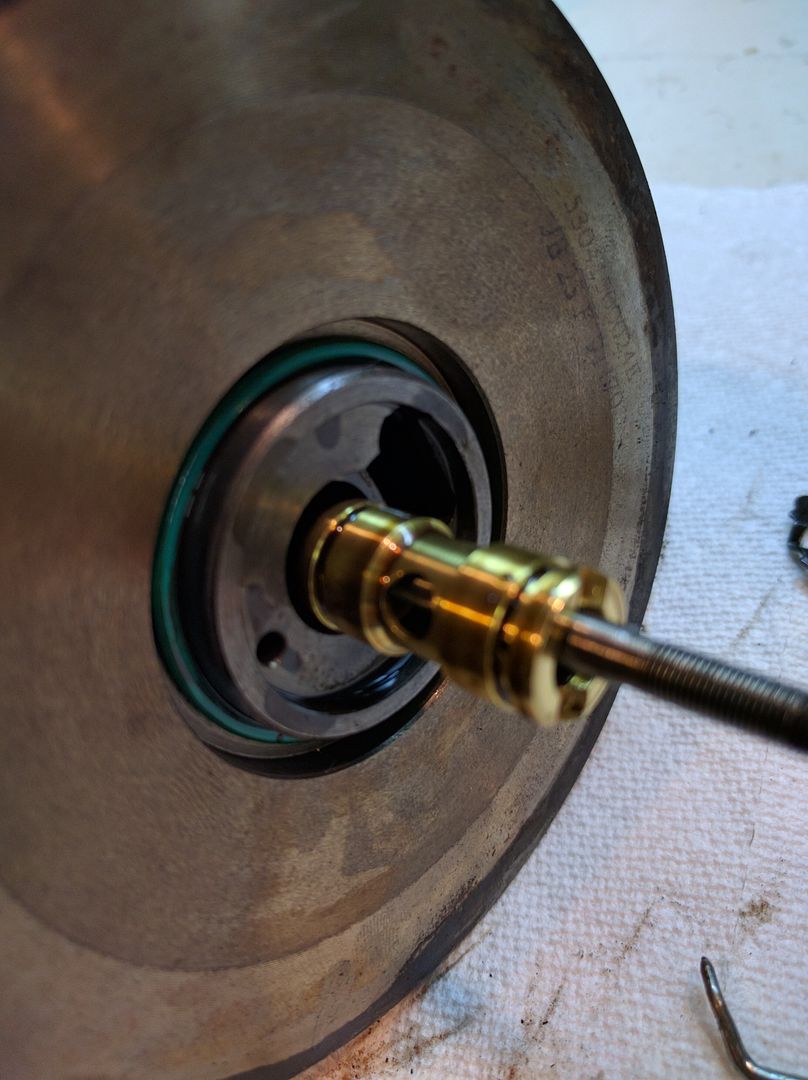

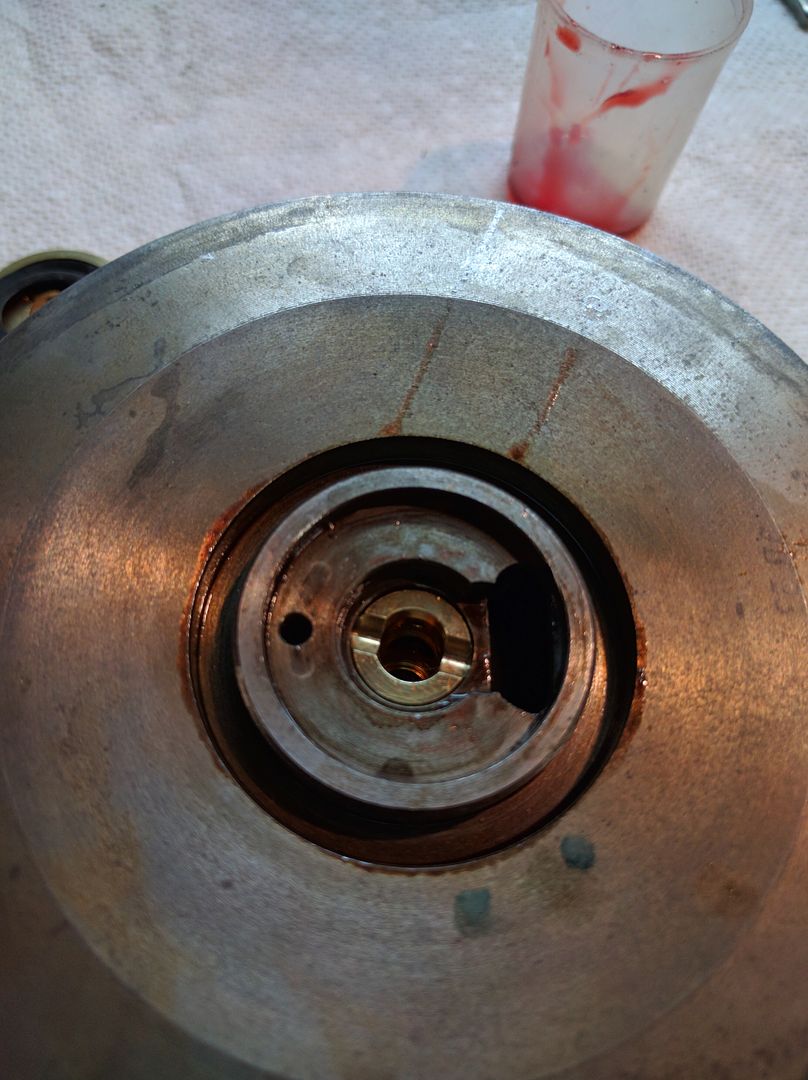

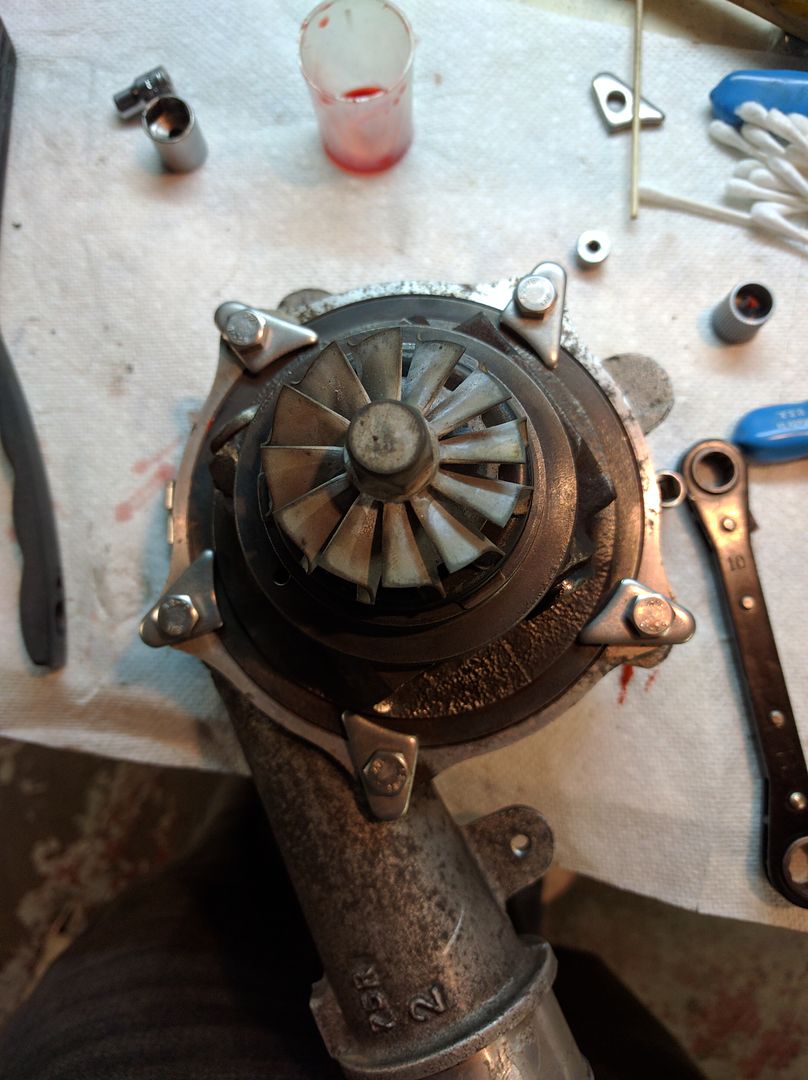

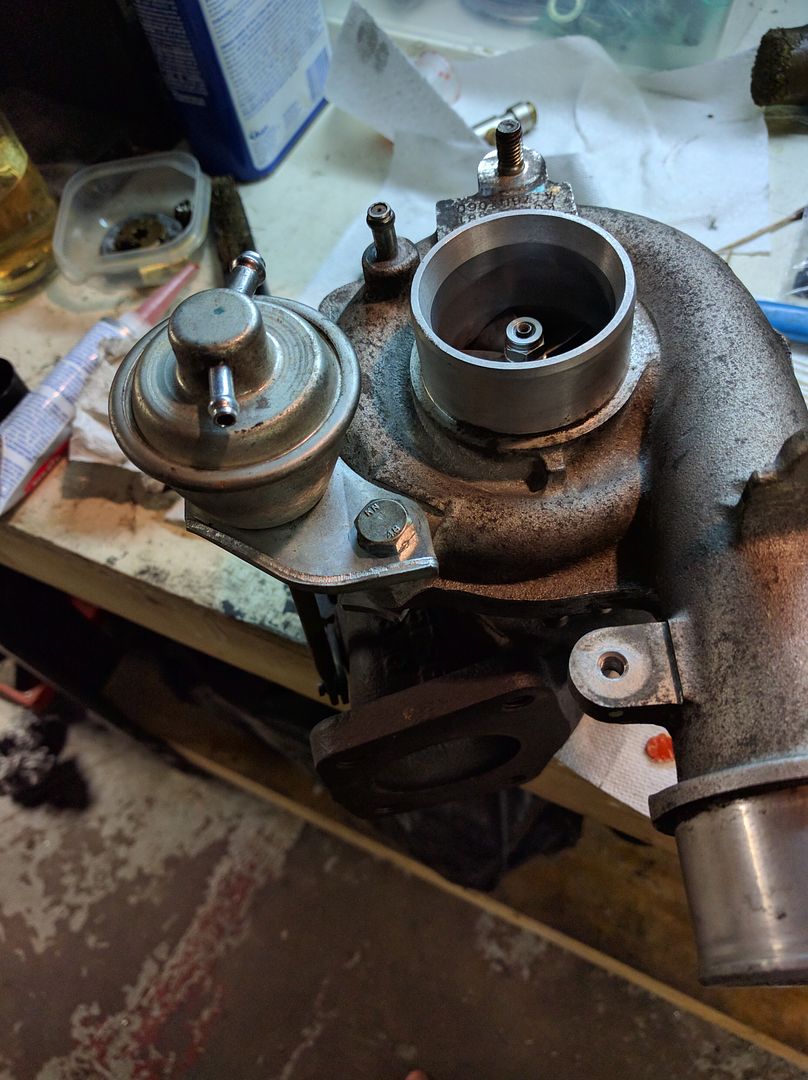

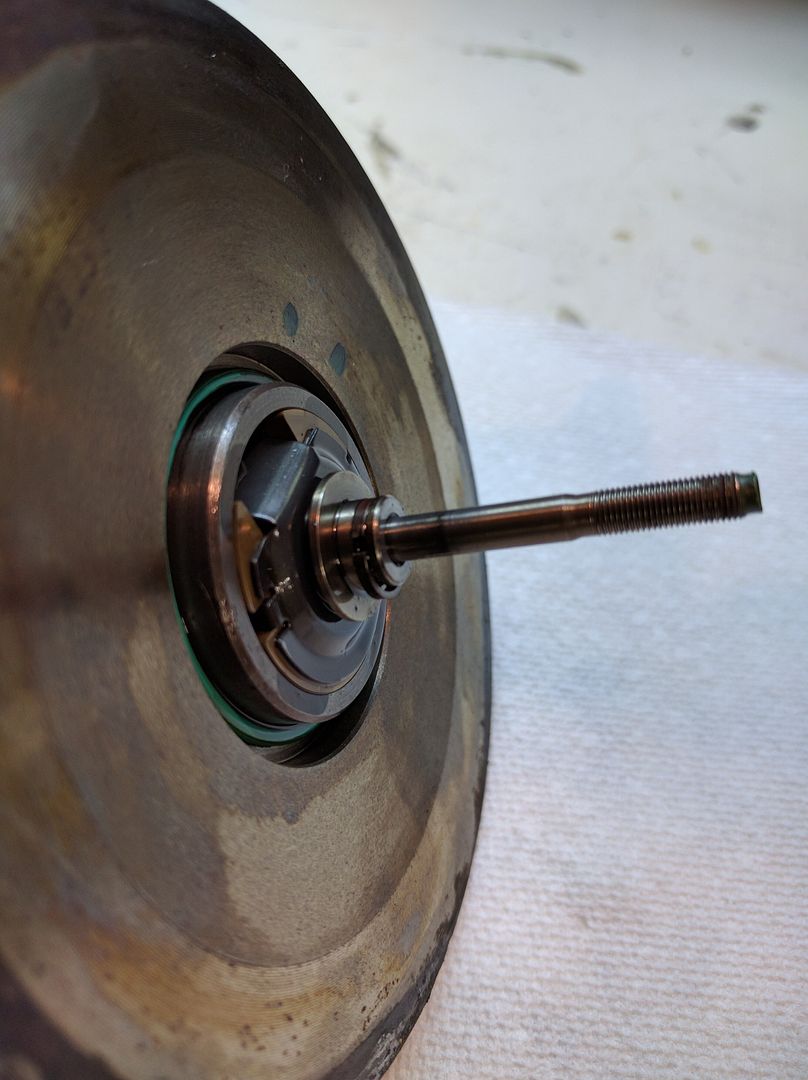

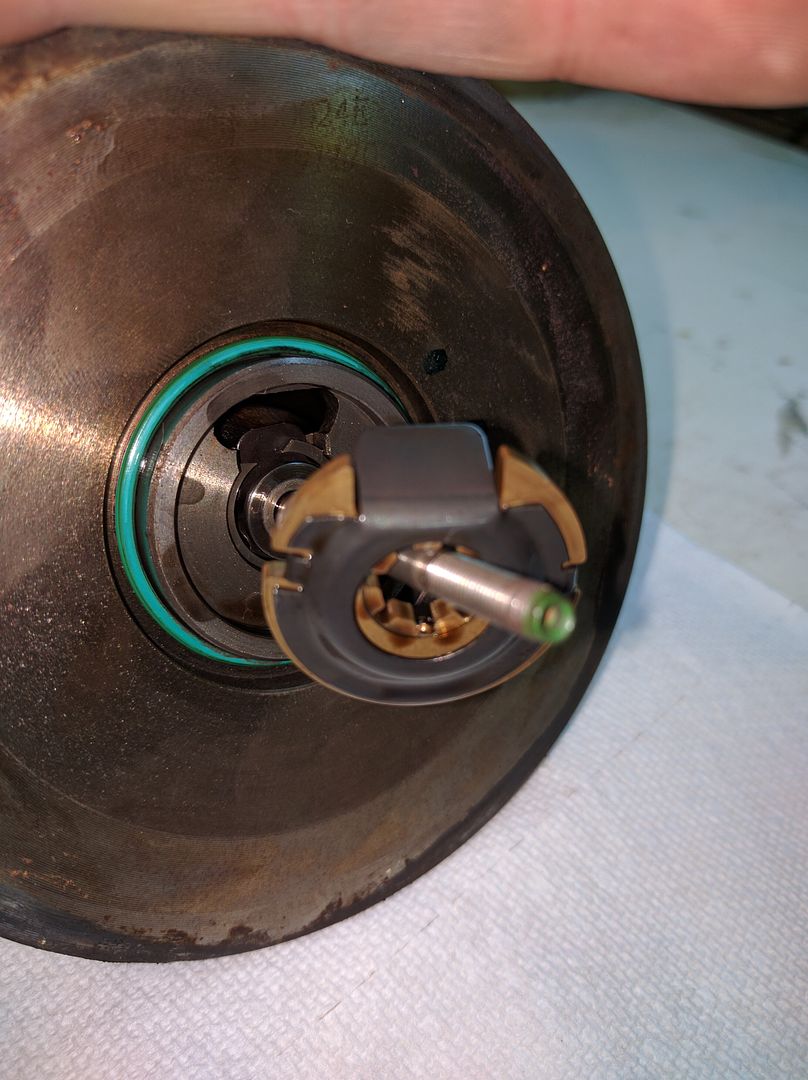

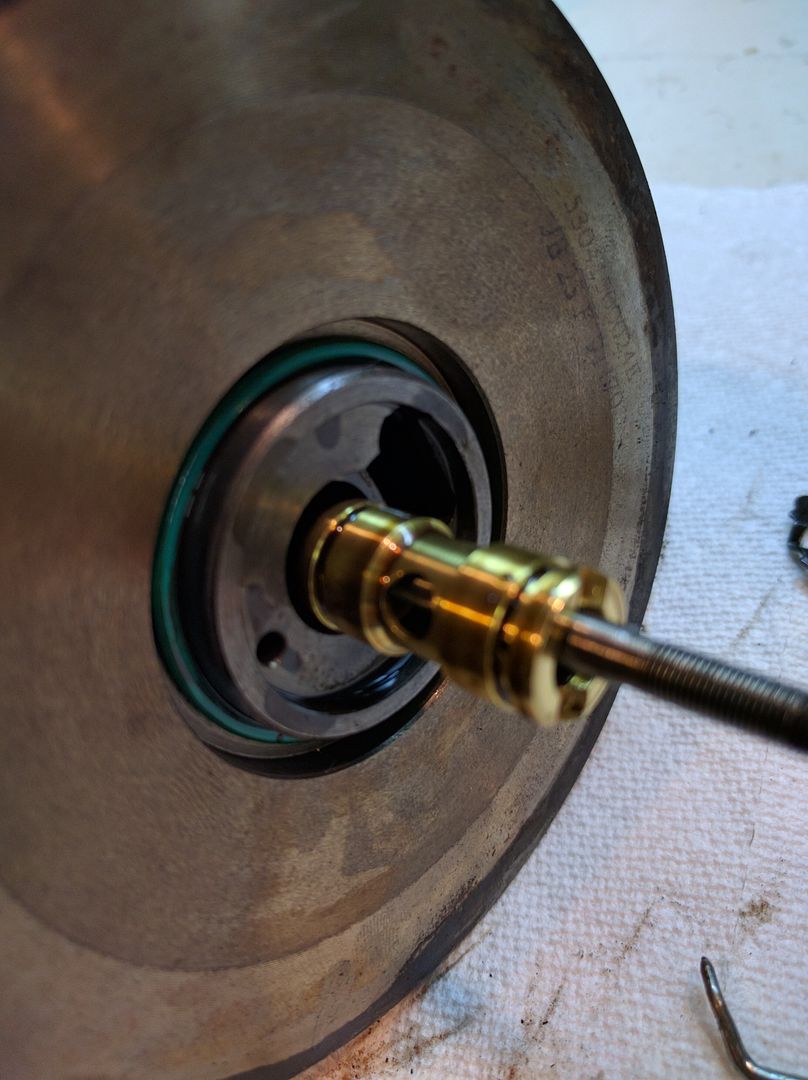

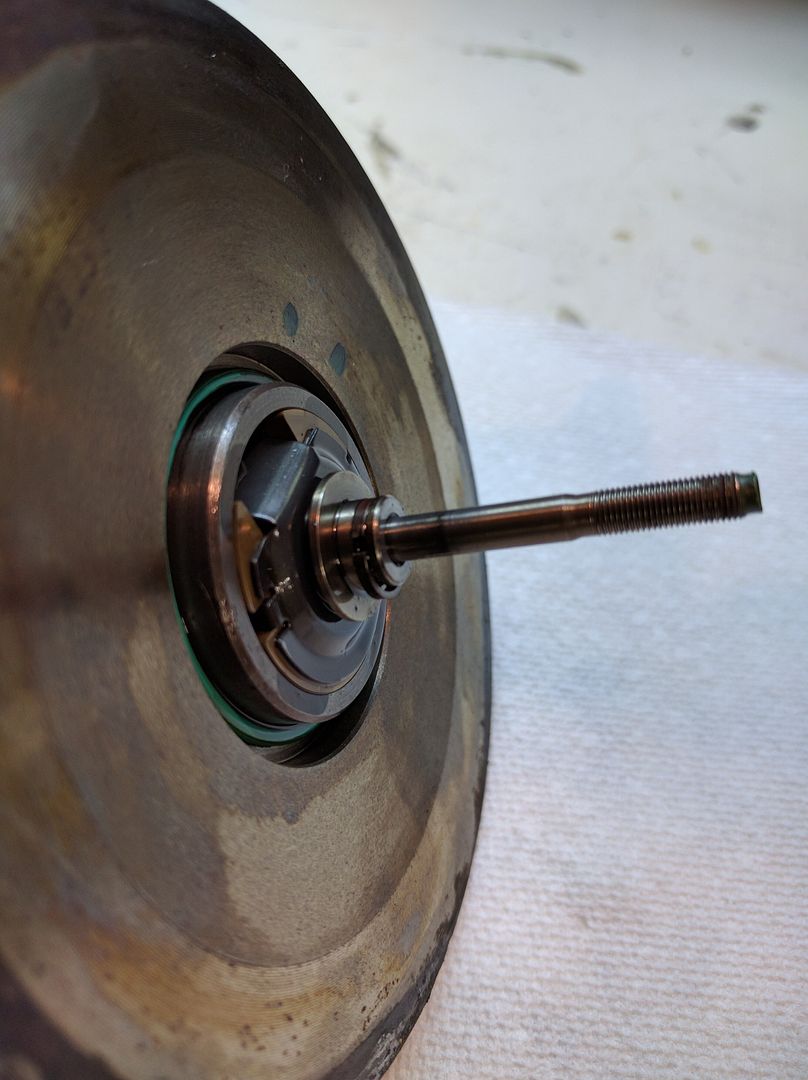

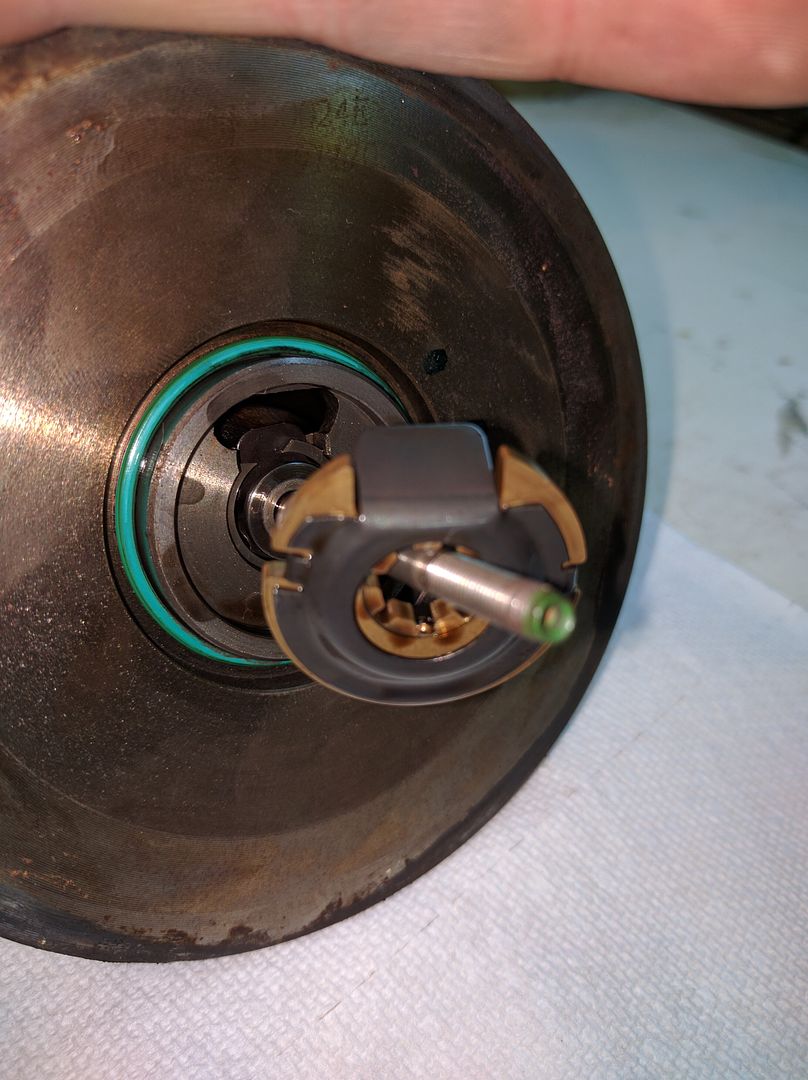

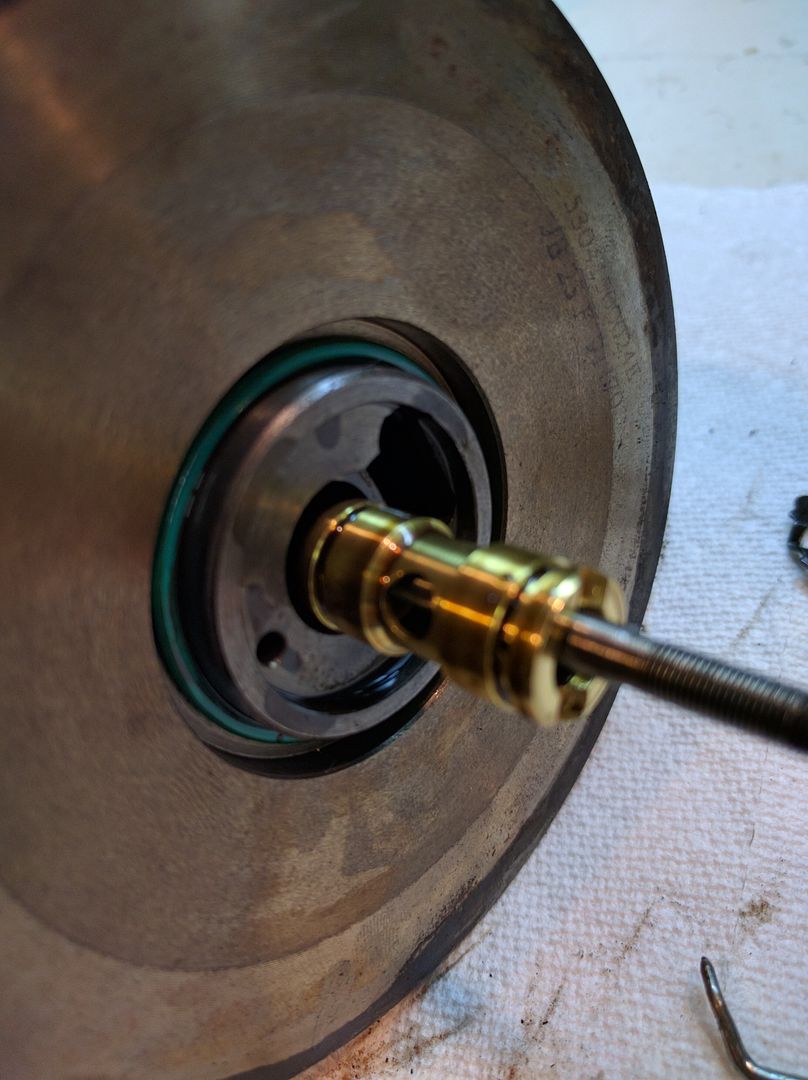

Compressor wheel comes off with housing- *** REVERSE THREADED NUT***

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.