I already posted all this somewhere else, but seeing as it's helpful I thought I would post this here.

I had a curiosity about vertical vs. horizontal FMICs for our cars.

I've been reading papers/articles/forums regarding vertical flow/horizontal flow front mount intercoolers.

The general consensus regarding flow aligns with a whitepaper from treadstone (below)-

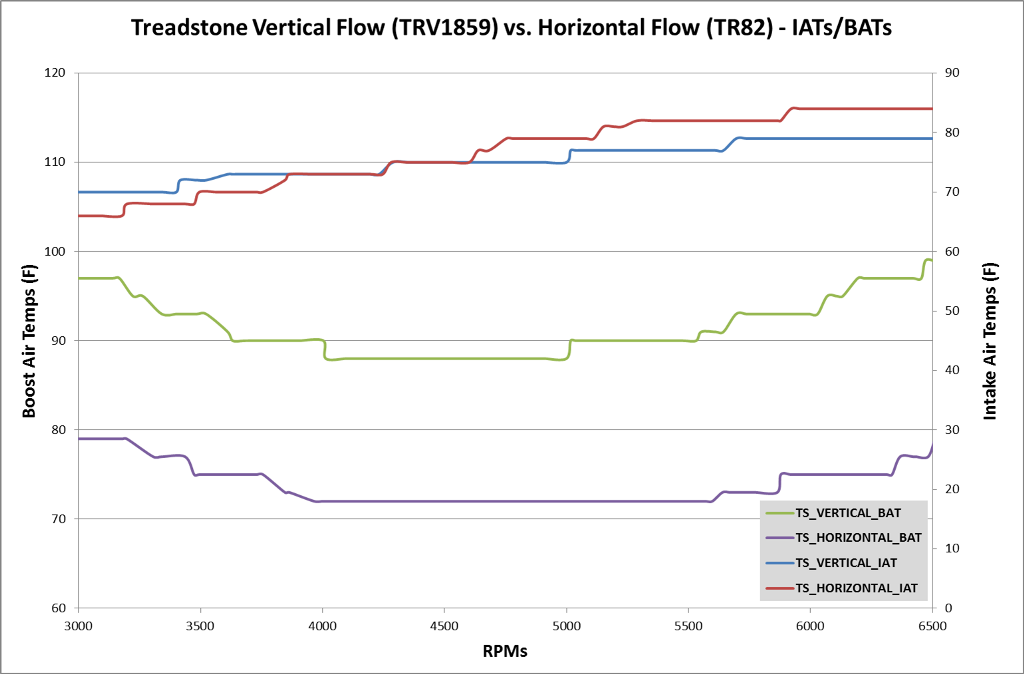

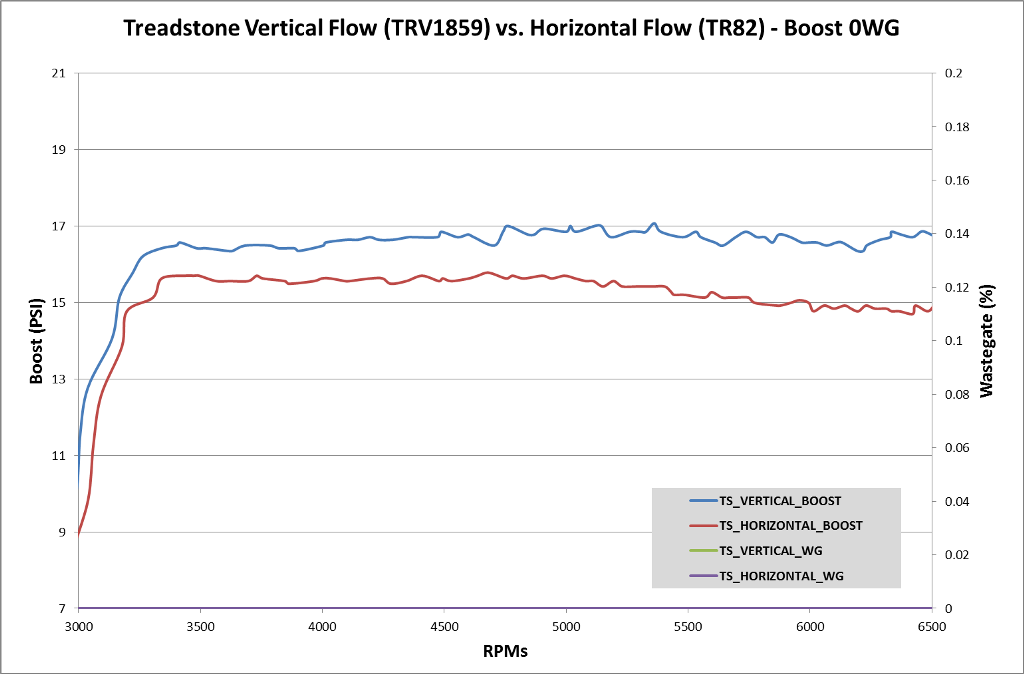

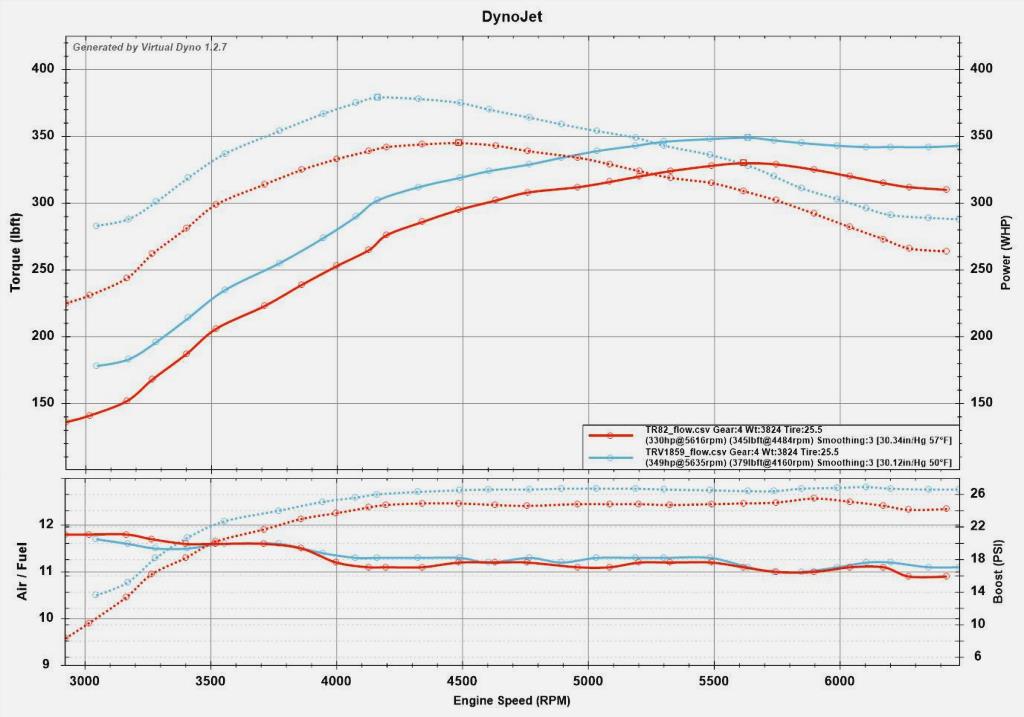

Vertical and horizontal flow cores that are manufactured exhibit different internal fin design characteristics. Horizontal flow coolers have long runner lengths which translate higher pressure drop through the core, while the vertical cores have short runner lengths and lower pressure drops. Inversely, vertical flow intercoolers have lower cooling efficiency compared to a longer runner horizontal flow.

In laymans terms:

shorter runs (vertical flow) = better flow/lower pressure drop/lower thermal efficiency

longer runs (horizontal flow) = lower flow/higher pressure drop/higher thermal efficiency

These general rules can be negated by the core design of course. A vertical flow core may be made more dense to increase efficiency and a horizontal flow core may be made less dense to increase flow/lower pressure drop.

Treadstone goes on to say the following; these statements generally align with what I have read in automotive tech articles and decent forums threads and it seems quite logical. That, and pretty much all small displacement turbo cars you see have OEM horizontal flow intercoolers.

Regarding vertical flow

Many vertical cores that we manufacture are designed for larger displacement motors that do not require high boost pressures, therefore we need a dense internal fin design to extract all the heat we can, as the airpasses through 6-10” of core length.

Regarding horizontal flow

Many smaller displacement motors 1.6L to 3.0L will require higher boost pressures 15psi and above, to achieve the power levels one is looking for. With this higher boost pressure means higher compressor outlet temp, and we need to cool this air over a longer runner length of intercooler. Making the runner length longer means higher pressure drop through core, and this is something that robs us of power. Manufacturing a slightlyless dense core than our vertical flow cores, we can still have low pressure drop through core, while still extracting as much heat as possible.

For my final act in this FMIC saga, I picked up a treadstone TR82 horizontal flow Intercooler. It has a similar size core (600^3in) to the existing TR1859 I'm using (582^3in). Although the core size is similar, the vertical flow TRV1859 is rated to 720HP and the horizontal TR82 to 500HP. The TR82 doesn't flow as well but will be much more thermally efficient.

TR82 below. Since my TRV1859 is same side inlet/outlet, I opted for the TR82 to reuse all of my piping.

I had a curiosity about vertical vs. horizontal FMICs for our cars.

I've been reading papers/articles/forums regarding vertical flow/horizontal flow front mount intercoolers.

The general consensus regarding flow aligns with a whitepaper from treadstone (below)-

Vertical and horizontal flow cores that are manufactured exhibit different internal fin design characteristics. Horizontal flow coolers have long runner lengths which translate higher pressure drop through the core, while the vertical cores have short runner lengths and lower pressure drops. Inversely, vertical flow intercoolers have lower cooling efficiency compared to a longer runner horizontal flow.

In laymans terms:

shorter runs (vertical flow) = better flow/lower pressure drop/lower thermal efficiency

longer runs (horizontal flow) = lower flow/higher pressure drop/higher thermal efficiency

These general rules can be negated by the core design of course. A vertical flow core may be made more dense to increase efficiency and a horizontal flow core may be made less dense to increase flow/lower pressure drop.

Treadstone goes on to say the following; these statements generally align with what I have read in automotive tech articles and decent forums threads and it seems quite logical. That, and pretty much all small displacement turbo cars you see have OEM horizontal flow intercoolers.

Regarding vertical flow

Many vertical cores that we manufacture are designed for larger displacement motors that do not require high boost pressures, therefore we need a dense internal fin design to extract all the heat we can, as the airpasses through 6-10” of core length.

Regarding horizontal flow

Many smaller displacement motors 1.6L to 3.0L will require higher boost pressures 15psi and above, to achieve the power levels one is looking for. With this higher boost pressure means higher compressor outlet temp, and we need to cool this air over a longer runner length of intercooler. Making the runner length longer means higher pressure drop through core, and this is something that robs us of power. Manufacturing a slightlyless dense core than our vertical flow cores, we can still have low pressure drop through core, while still extracting as much heat as possible.

For my final act in this FMIC saga, I picked up a treadstone TR82 horizontal flow Intercooler. It has a similar size core (600^3in) to the existing TR1859 I'm using (582^3in). Although the core size is similar, the vertical flow TRV1859 is rated to 720HP and the horizontal TR82 to 500HP. The TR82 doesn't flow as well but will be much more thermally efficient.

TR82 below. Since my TRV1859 is same side inlet/outlet, I opted for the TR82 to reuse all of my piping.