JohnnyTightlips

Motorhead

Looks good. http://www.hitunedperformance.com/5-8-hose-extension-kit/ This is what people use to make the coolant line longer so it tucks under nicer. You can also just get a brass one from a local hardware store.@Duey1083 I bought what Justin recommended. The closest thing I did to research on plugs was finding the best price. They are NGK 6510's

@Db09ms3 haha! WilCo!

*************************************************

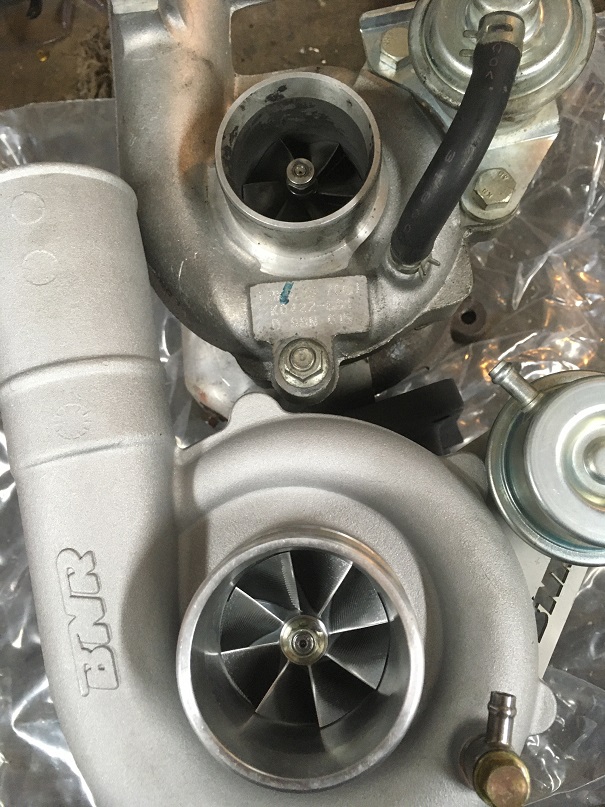

Sitting/working at my kitchen table yesterday when the dog freaked out=Package at the door. Of course work is done for the day at that point. Like anyone could focus on work when a Turbo is sitting there!

I pulled it out to take a look and compare. It is noticeably larger! I expected it to be slightly larger but not this much. I am in love! I kind of feel bad for stuffing down and hiding in my engine bay. Also, check out all the Laser Cut BNR logos.

Started swapping parts and getting things put back together. There is TONS if info out there about how to do this so I am not going to give a blow by blow but here are the only "issues" I have had so far:

The threaded stud on the bottom of the turbo does not come with the BNR and you need to transfer it over. Mine was BARELY long enough to get 2 nuts on it and jamb together, to get it off. I ended up with a damaged thread and had to run a die over it to clean it up.

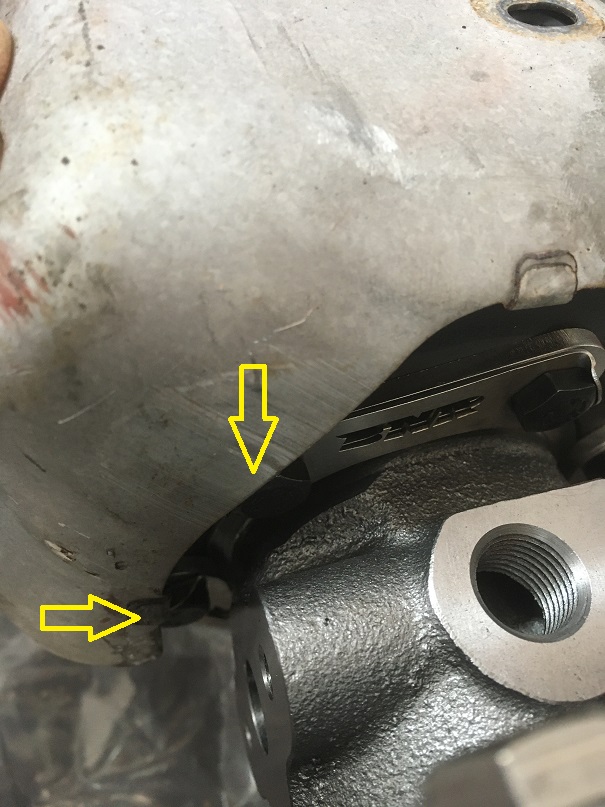

The heat shield that goes around the bottom interfered, ever so slightly, with the lock bolts and plates.

Nothing a set of tin snips and pliers couldn't fix.

After that, it all pretty much bolted together like I would expect. All the heat shields and bracketry fit like factory. It comes with new stainless studs for the exhaust manifold and down pipe; I was not going to use the stock nuts on those stainless studs so I went to my local hardware store and picked up some new stainless nuts. Those {badword} nuts were $2.69 EACH!!! I spent almost $30 on 9 nuts!!

One of my pet peeves is un-torqued hardware. I spent a good hour trying to figure out how to get a torque wrench on the down pipe nuts. Different combinations of deep and shallow sockets, different lengths and different types of extensions, and even 2 different types of torque wrenches and the only nut I could torque was middle top one. It's not that I could not get the wrench and socket on there'. It's that there is not enough room to deflect the torque wrench to get a good reading. The other 4 got the good ol' fashioned, "That seems about 50 foot pounds" treatment.

Last "Issue": The new coupler for my inlet interferes with a coolant pipe. I didn't spend much time on this and will figure it out later. I am not too worried about it.

So here's how it looked when I went to bed last night. I probably put about 4 hours of work in, taking my sweet time. I also killed a good 20 minutes looking for one of the #$^%^ expensive nuts when I dropped it. Car is off jack stands. Honestly, this really is "bolt on"; super easy to install. I expected at least some holes to not line up or heat shields that would need to be adjusted but just the one at the top. You'll notice all my "issues" I described above are completely minor annoyances more than anything. I am pretty psyched to get it started! Once my boost controller gets here, I will finish it up. Still back ordered....