Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

Style variation

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

El Sodomisator

- Thread starter Tomas

- Start date

- Watchers 14

lasangelos

Greenie Member

Wow first time I’ve seen the car, but that battery is truly impressive

Yesterday I switched BOV & went to bed lol it be like that sometimes

Can’t wait to spam your previous posts

Cool shit !

Sent from my iPhone using Tapatalk

Yesterday I switched BOV & went to bed lol it be like that sometimes

Can’t wait to spam your previous posts

Cool shit !

Sent from my iPhone using Tapatalk

Tomas

Greenie N00B Member

This has been the longest I've had teh 6 out of action. Almost a year.

Had some noob fails and also made some progress. Noob fail was installing the MAF sensor housing the wrong way, which took me about a month to figure out after doing all kinds of other shit that wasn't the problem, and progress was the following;

1. Diaper fits now. Not completely done but the main construction is complete. It latches with quick disconnects to the subframe and then M6 rivnuts secure it. I wouldnt say it's one of those splitters where a couple of dudes step on it and bounce around with big grins on their faces but it feels perrrty sturdy nonetheless.

2. Cockpit gauges of gheyness done. Looks very ghey and I like it with the exception of the AP which sits a bit low and gets bump fisted when shifting sometimes . May have to lift it an inch or so.

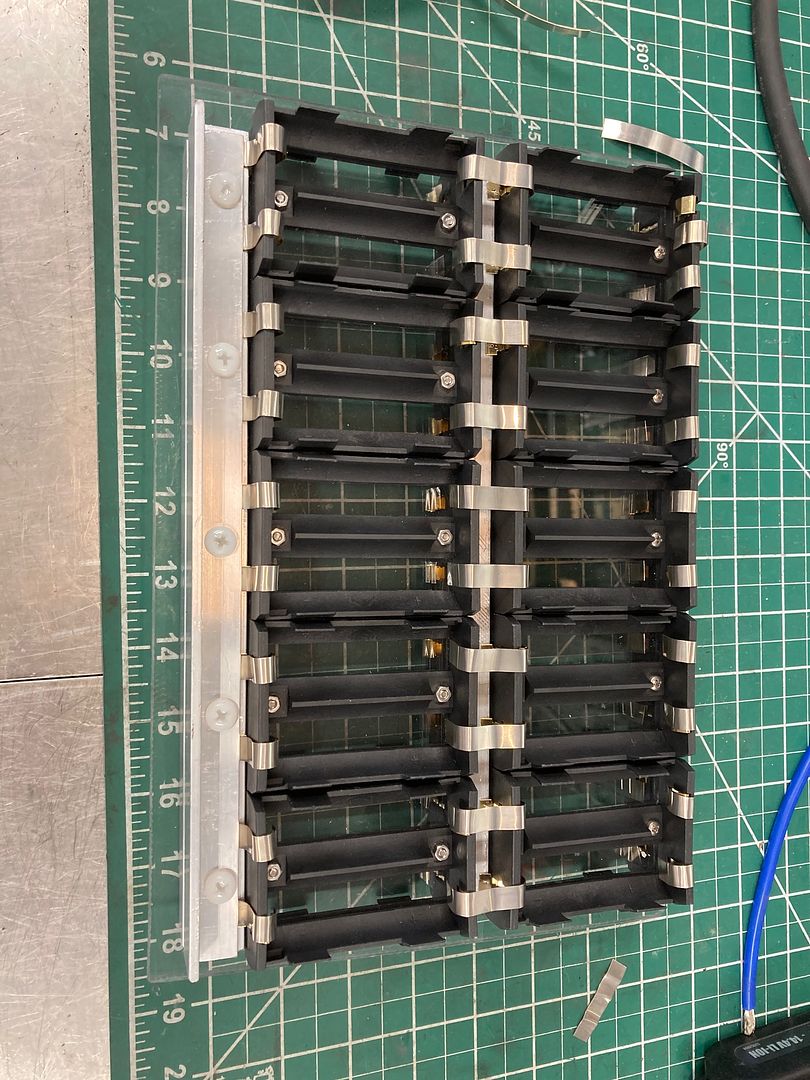

3. Fucking DIY lifepo battery has taken me down a rabbit hole of self sufficient dreams of energy independence and off-grid living and endless hours of interwebz searching. For the purpose of the 6 I'll just say the battery works but I am not 100% happy with it.

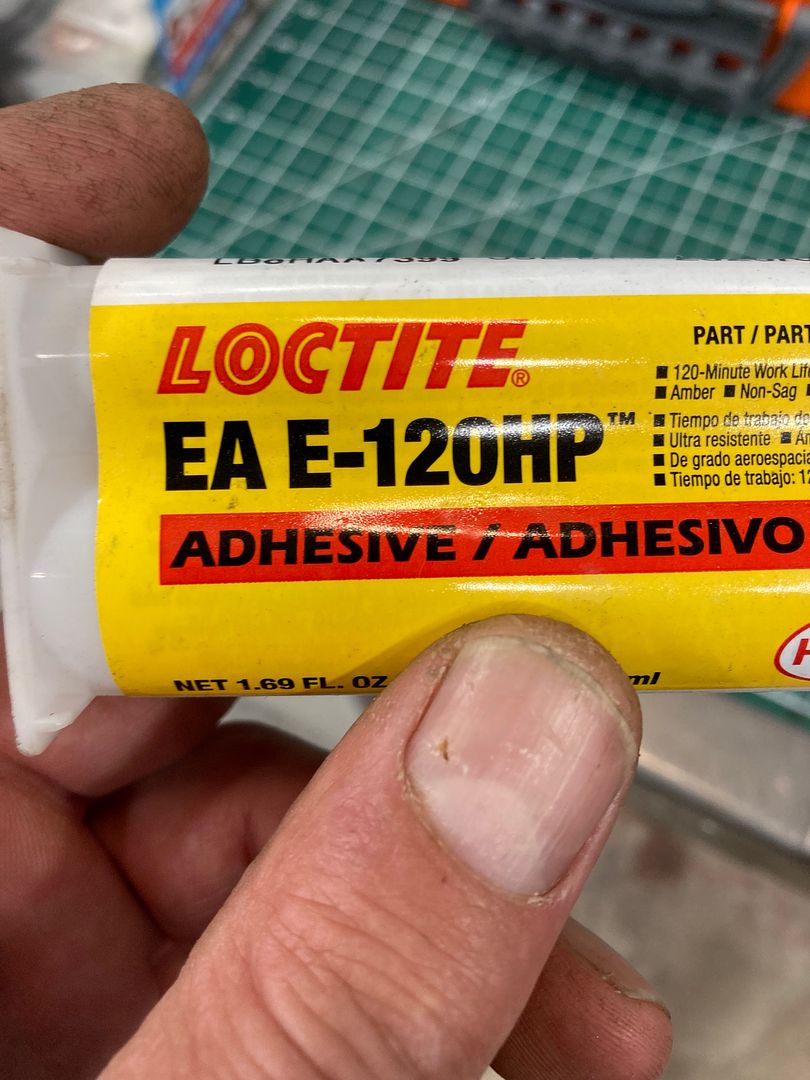

4. The god damn summabitch Ford plastic IM I glued together to the FI bar leaks in several places. I guess i'll add more of that fancy aerospace epoxy and if that does not fix it I really don't know. The Damond set up is ok but its not great from my perspective.

5. The traction wiggley light is on. Hope its not the coil in the rear diff.

6. Replaced some seals in the transfer case. It looks like the oil drain pipe is leaking however so I may have to take the while TC down.

7. The throttle blipper for cheating heal and toeing works pretty good. Wish it was a bit faster in blipping the trottle. I have it on the lowest possible delay and it could still be faster but it is still a good gadget for track duty IMO.

Otherwise the car drives peachy, Did a couple of tunrpike drives and the aero seems to work pretty good. Car feels more stable at high speed and planted on the few turns I was able to take at speed. Rear wing angle of attack (AOA) is about 6 degrees for the lower wing and 35 for the upper one.

.jpg?width=1920&height=1080&fit=bounds)

Had some noob fails and also made some progress. Noob fail was installing the MAF sensor housing the wrong way, which took me about a month to figure out after doing all kinds of other shit that wasn't the problem, and progress was the following;

1. Diaper fits now. Not completely done but the main construction is complete. It latches with quick disconnects to the subframe and then M6 rivnuts secure it. I wouldnt say it's one of those splitters where a couple of dudes step on it and bounce around with big grins on their faces but it feels perrrty sturdy nonetheless.

2. Cockpit gauges of gheyness done. Looks very ghey and I like it with the exception of the AP which sits a bit low and gets bump fisted when shifting sometimes . May have to lift it an inch or so.

3. Fucking DIY lifepo battery has taken me down a rabbit hole of self sufficient dreams of energy independence and off-grid living and endless hours of interwebz searching. For the purpose of the 6 I'll just say the battery works but I am not 100% happy with it.

4. The god damn summabitch Ford plastic IM I glued together to the FI bar leaks in several places. I guess i'll add more of that fancy aerospace epoxy and if that does not fix it I really don't know. The Damond set up is ok but its not great from my perspective.

5. The traction wiggley light is on. Hope its not the coil in the rear diff.

6. Replaced some seals in the transfer case. It looks like the oil drain pipe is leaking however so I may have to take the while TC down.

7. The throttle blipper for cheating heal and toeing works pretty good. Wish it was a bit faster in blipping the trottle. I have it on the lowest possible delay and it could still be faster but it is still a good gadget for track duty IMO.

Otherwise the car drives peachy, Did a couple of tunrpike drives and the aero seems to work pretty good. Car feels more stable at high speed and planted on the few turns I was able to take at speed. Rear wing angle of attack (AOA) is about 6 degrees for the lower wing and 35 for the upper one.

.jpg?width=1920&height=1080&fit=bounds)

Last edited:

JohnnyTightlips

Motorhead

This has been the longest I've had teh 6 out of action. Almost a year.

Had some noob fails and also made some progress. Noob fail was installing the MAF sensor housing the wrong way, which took me about a month to figure out after doing all kinds of other shit that wasn't the problem, and progress was the following;

1. Diaper fits now. Not completely done but the main construction is complete. It latches with quick disconnects to the subframe and then M6 rivnuts secure it. I wouldnt say it's one of those splitters where a couple of dudes step on it and bounce around with big grins on their faces but it feels perrrty sturdy nonetheless.

2. Cockpit gauges of gheyness done. Looks very ghey and I like it with the exception of the AP which sits a bit low and gets bump fisted when shifting sometimes . May have to lift it an inch or so.

3. Fucking DIY lifepo battery has taken me down a rabbit hole of self sufficient dreams of energy independence and off-grid living and endless hours of interwebz searching. For the purpose of the 6 I'll just say the battery works but I am not 100% happy with it.

4. The god damn summabitch Ford plastic IM I glued together to the FI bar leaks in several places. I guess i'll add more of that fancy aerospace epoxy and if that does not fix it I really don't know. The Damond set up is ok but its not great from my perspective.

5. The traction wiggley light is on. Hope its not the coil in the rear diff.

6. Replaced some seals in the transfer case. It looks like the oil drain pipe is leaking however so I may have to take the while TC down.

7. The throttle blipper for cheating heal and toeing works pretty good. Wish it was a bit faster in blipping the trottle. I have it on the lowest possible delay and it could still be faster but it is still a good gadget for track duty IMO.

Otherwise the car drives peachy, Did a couple of tunrpike drives and the aero seems to work pretty good. Car feels more stable at high speed and planted on the few turns I was able to take at speed. Rear wing angle of attack (AOA) is about 6 degrees for the lower wing and 35 for the upper one.

Just JBweld the intake manifold.

Just literally coat the entire outside of the intake manifold in like .25 inches of jb weld

Tomas

Greenie N00B Member

Standard Epoxy compounds like JB weld dissolve with ethanol containing fuels. That's why I used the Henkel / Loctite E-120HP. It is one of the few Epoxies which will not dissolve with Ethanol.

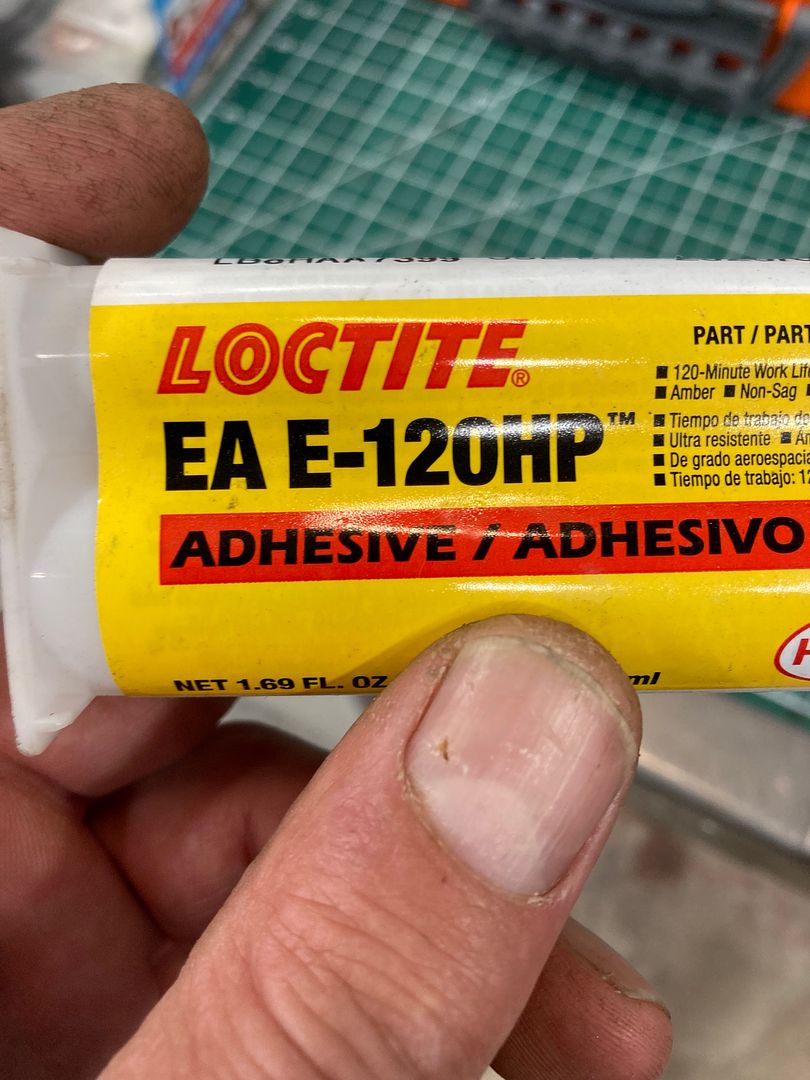

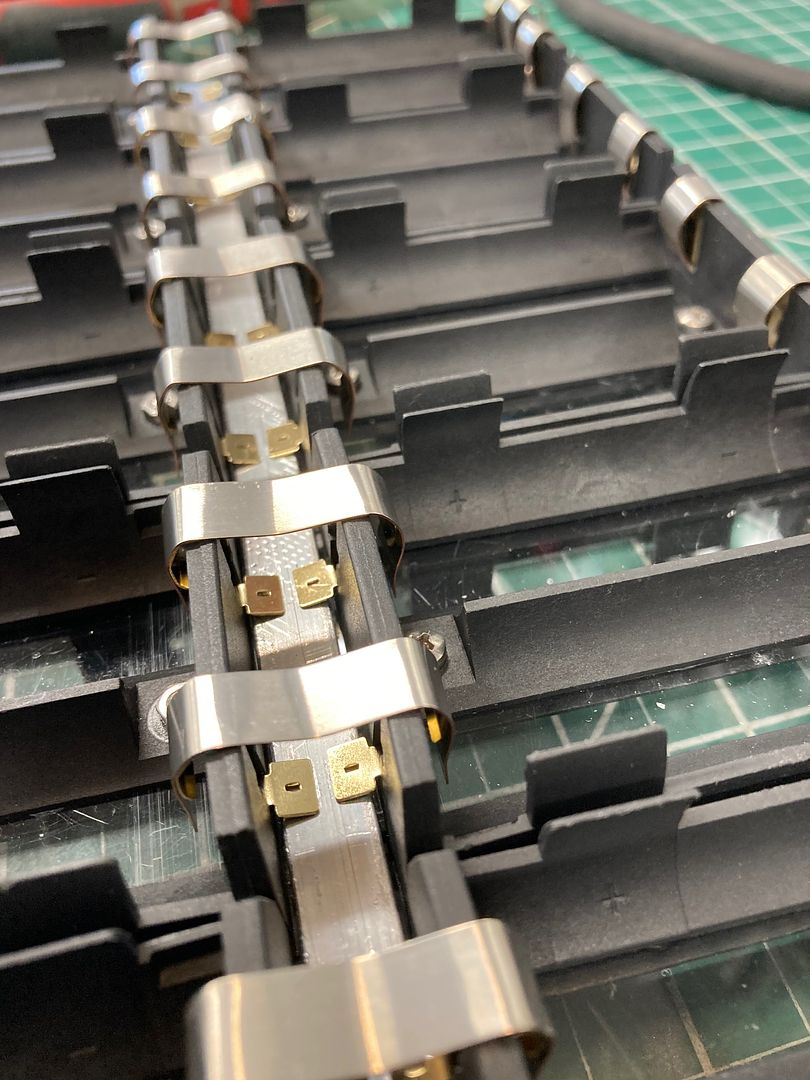

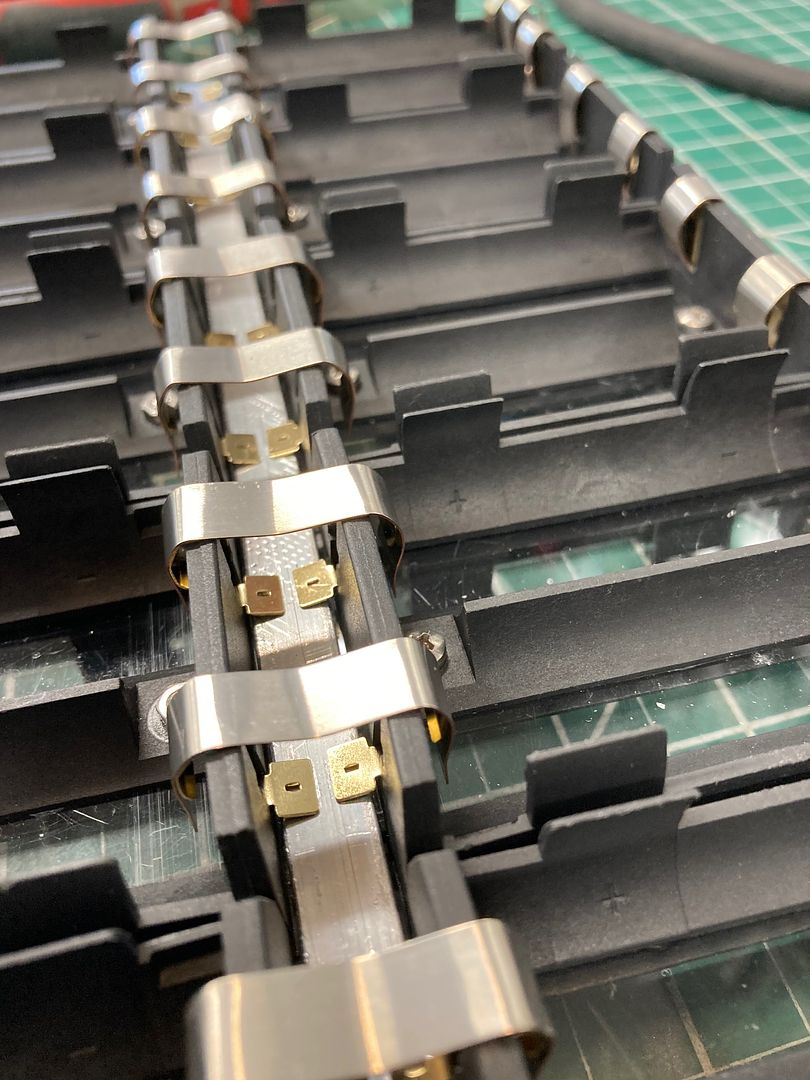

As to the series connections on the battery being soldered to the copper bars the strips are 8mm wide and 0.4mm thick tinned copper. Punching a hole through the strips would work when you clamp them down the strips distort due to the torque of the head of the screw. The AWG2 cables from the bus bars to the connector and AWG8 cable to the switch are crimped ringed terminal bolted down however.

.jpg?width=1920&height=1080&fit=bounds)

.jpg?width=1920&height=1080&fit=bounds)

As to the series connections on the battery being soldered to the copper bars the strips are 8mm wide and 0.4mm thick tinned copper. Punching a hole through the strips would work when you clamp them down the strips distort due to the torque of the head of the screw. The AWG2 cables from the bus bars to the connector and AWG8 cable to the switch are crimped ringed terminal bolted down however.

.jpg?width=1920&height=1080&fit=bounds)

.jpg?width=1920&height=1080&fit=bounds)

JohnnyTightlips

Motorhead

I have jbwelded my intake manifold and my intake. I not seen any softening or issues and the car has been going 2 years with PI and an e50 blend for 1 of those years. I also found this video, maybe you could do a similar test. I just wonder if your concerns are practical for this application as it will see very little fuel on it will def not be soaking in it.

jsmith

Silver Member

Tomas,

Maybe a 2nd bus bar over those solder joints, sandwich style, with some conductive adhesive (or even a thermal pad if you want to disassemble) to bridge any gaps? If it re-flows that would at least keep them from moving terribly far.

Solder has the potential to re-flow at a reasonably low temperature. As low as 90 deg C according to a quick googling. (https://www.ametek-ecp.com/resources/blog/2019/may/what-is-solder-melting-point). If the solder used flows at the lower end of the range you could park a hot car in the summer sun and come back to not so great connections. When you add the amperage to start a car it may heat up even more.

I think this concern is why most electric car manufacturers weld, instead of solder, the contacts onto their batteries.

Maybe a 2nd bus bar over those solder joints, sandwich style, with some conductive adhesive (or even a thermal pad if you want to disassemble) to bridge any gaps? If it re-flows that would at least keep them from moving terribly far.

What's wrong with the battery?

Solder has the potential to re-flow at a reasonably low temperature. As low as 90 deg C according to a quick googling. (https://www.ametek-ecp.com/resources/blog/2019/may/what-is-solder-melting-point). If the solder used flows at the lower end of the range you could park a hot car in the summer sun and come back to not so great connections. When you add the amperage to start a car it may heat up even more.

I think this concern is why most electric car manufacturers weld, instead of solder, the contacts onto their batteries.

Tomas

Greenie N00B Member

I have jbwelded my intake manifold and my intake. I not seen any softening or issues and the car has been going 2 years with PI and an e50 blend for 1 of those years. I also found this video, maybe you could do a similar test. I just wonder if your concerns are practical for this application as it will see very little fuel on it will def not be soaking in it.

The faggot in the video uses standard gas which has less than 15% e.

If you use meth on top of a high ethanol mix that test will be useless.

Sorry but saving $15 by going JB weld against an industrial grade Epoxy with a data sheet that specifically tests the epoxy against several solvents is just not worth it IMO. If you can find a JB weld data sheet like this one I'd be very impressed

http://tds.henkel.com/tds5/Studio/ShowPDF/243 NEW-EN?pid=EA E-120HP&format=MTR&subformat=REAC&language=EN&plant=WERCS

Tomas

Greenie N00B Member

Tomas,

Maybe a 2nd bus bar over those solder joints, sandwich style, with some conductive adhesive (or even a thermal pad if you want to disassemble) to bridge any gaps? If it re-flows that would at least keep them from moving terribly far.

Solder has the potential to re-flow at a reasonably low temperature. As low as 90 deg C according to a quick googling. (https://www.ametek-ecp.com/resources/blog/2019/may/what-is-solder-melting-point). If the solder used flows at the lower end of the range you could park a hot car in the summer sun and come back to not so great connections. When you add the amperage to start a car it may heat up even more.

I think this concern is why most electric car manufacturers weld, instead of solder, the contacts onto their batteries.

Yeah that second bus bar sandwhich would work . Already spent too much god damn time on that battery though. May be some day I'll upgrade it.

Tomas

Greenie N00B Member

Thanks but no. This is more of a learning experience for me. I could also source high drain Lifepo cells from China that will do the trick but thats not what its about. Like these ones:

https://www.aliexpress.com/item/4000002867586.html

https://www.aliexpress.com/item/4000002867586.html

Tomas

Greenie N00B Member

I almost burned my balls off.

So after expermienting with Lifepo batteries I started using Li-ion and I totally underestimated the violence of these fucking cells. I secured one of the cell holder with a 14mm instead of a 12mm one and since the screw was protruding too much when I pressed the cell in the holder it punctured it and KABOOM. My wife came running from the yard into the garage yelling if I was ok lol.

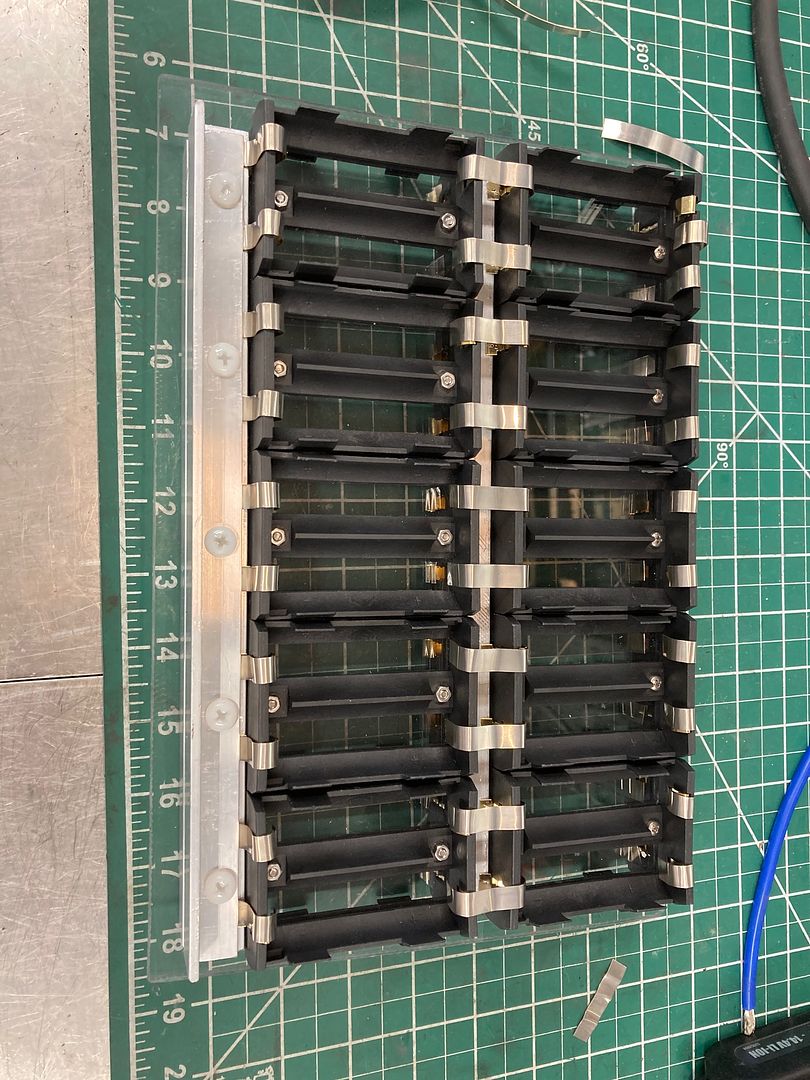

I am also making a larger 40 cell battery for the Ridgeline. No soldering on this one.

Also finally took the time to wiggle the T-case out of place to change out the terboh drain pipe. That shit with the hose connecting the two ends was never a good idea. I also don't think using AN-lines is a good idea. I made myself a jig and hard soldered a piece of SS tube instead. The solder has a 1100F melting point so it should be ok.

So after expermienting with Lifepo batteries I started using Li-ion and I totally underestimated the violence of these fucking cells. I secured one of the cell holder with a 14mm instead of a 12mm one and since the screw was protruding too much when I pressed the cell in the holder it punctured it and KABOOM. My wife came running from the yard into the garage yelling if I was ok lol.

I am also making a larger 40 cell battery for the Ridgeline. No soldering on this one.

Also finally took the time to wiggle the T-case out of place to change out the terboh drain pipe. That shit with the hose connecting the two ends was never a good idea. I also don't think using AN-lines is a good idea. I made myself a jig and hard soldered a piece of SS tube instead. The solder has a 1100F melting point so it should be ok.

Glad to hear your genitals are still fine and working. That would have been one last bang to end them all.

JohnnyTightlips

Motorhead

Congrats on still being alive and not on fire. I am sure if you used a suitable hose material for the oil drain it probably would have worked just fine but the stainless sleeve will for sure work lol. https://www.ebay.com/itm/Turbo-Oil-...612932?hash=item5956753bc4:g:LfYAAOxyW9RRWx-Z

Have you always smoked or did you go buy a pack in response to blowing yourself up?