So sorry to hear what happened man.. Also, I have coilovers as well and hope mine do no end up seized as well. Mine are set as high as they go at least tho.

Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

Style variation

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

JohnnyTightlips Build "Maximum Carnage"

- Thread starter JohnnyTightlips

- Start date

- Watchers 48

-

- Tags

- 56k warning gen juan zzb

JohnnyTightlips

Motorhead

Update:

While my car was down I decided to make sure I had the trans full of fluid. I had put 3 quarts in it but since it was a full rebuild I assumed it needed more. It took about 3/4 more so take note anyone doing a tear down of a trans to buy 4 quarts. While I was adding fluid I noticed that some air was leaking out when I took the fill cap out. There should not be pressurized air in the trans. This told me the breather was not working which also told me that might be the reason I am getting some trans oil leaking out.

I found this thread https://www.mazdaspeeds.org/index.php?threads/transmission-breather-crack-pressure.5658/ and decided to do the AL mod and replace the rubber seal. My breather was brand new but the rubber must have been stuck from sitting on the shelf.

As soon as I took it for a drive I noticed shifts felt better. Less resistance to get it into gear. I was noticing before that it was a little more effort to get it into gear but I had chalked it up to me just not shifting well/being lazy with my shifts. Turns out it was air in the trans. Thanks @Mauro_Penguin for your thread on that.

Now onto the suspension. I got my locking rings in the mail from Megan Racing. They fit perfect.

After some trial and error I got the height as close as I could and wanted. The car is def taller up front and I can finally get a normal jack under it. I was able to raise the back just a little but I am out of adjustment back there. I also scheduled to get an alignment today. I have my winters on now as the daily temp is around 40f.

On another note I found my FPR that I had been using on my 90 Laser RS back in 2008 it is still in great shape and just needs a new diaphragm so I will be using that on my PI setup. I have decided to go with a hellcat pump. Here is the plan.

Not sure when I will have time to do all that. My wife was pretty over it sitting in the garage for 2 weeks while I waited on suspension bits.

While my car was down I decided to make sure I had the trans full of fluid. I had put 3 quarts in it but since it was a full rebuild I assumed it needed more. It took about 3/4 more so take note anyone doing a tear down of a trans to buy 4 quarts. While I was adding fluid I noticed that some air was leaking out when I took the fill cap out. There should not be pressurized air in the trans. This told me the breather was not working which also told me that might be the reason I am getting some trans oil leaking out.

I found this thread https://www.mazdaspeeds.org/index.php?threads/transmission-breather-crack-pressure.5658/ and decided to do the AL mod and replace the rubber seal. My breather was brand new but the rubber must have been stuck from sitting on the shelf.

As soon as I took it for a drive I noticed shifts felt better. Less resistance to get it into gear. I was noticing before that it was a little more effort to get it into gear but I had chalked it up to me just not shifting well/being lazy with my shifts. Turns out it was air in the trans. Thanks @Mauro_Penguin for your thread on that.

Now onto the suspension. I got my locking rings in the mail from Megan Racing. They fit perfect.

After some trial and error I got the height as close as I could and wanted. The car is def taller up front and I can finally get a normal jack under it. I was able to raise the back just a little but I am out of adjustment back there. I also scheduled to get an alignment today. I have my winters on now as the daily temp is around 40f.

On another note I found my FPR that I had been using on my 90 Laser RS back in 2008 it is still in great shape and just needs a new diaphragm so I will be using that on my PI setup. I have decided to go with a hellcat pump. Here is the plan.

- Hellcat Pump

- 6an line to firewall , y adapter, Line A , Line B

- Line A to HPFP

- Line B to JMF fuel rail

- Fuel Rail to FPR

- FPR Return to OEM line for return to basket

Not sure when I will have time to do all that. My wife was pretty over it sitting in the garage for 2 weeks while I waited on suspension bits.

Glad to see more progress man keep it up! That thing is going to be a freight train!

JohnnyTightlips

Motorhead

PI Update:

I am getting closer to getting PI going. Plan is same as before.

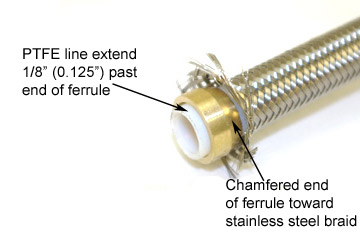

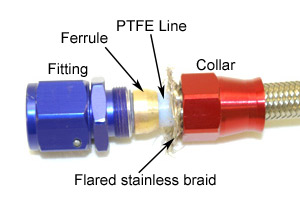

Hardest part was getting the coupler on the sleeve but I found that using a socket and a hand socket wrench to push and twist made it really easy.

19mm Socket Worked Better - 6an

This was really just a test to see how much work it would be to get them on but it was not too bad. This site was a big help.

http://anfittingguide.com/install-ptfe-hose-fittings/

My Fuel Pressure Regulator is from my 90 Laser RS which is dead and I ordered new internals so it should work great. I am trying to mount it here if I can. Easy to access and see if there are leaks. Also might try and route the line under the rail to a 180 fitting

I am still waiting on a few fittings. Once I get this all plumbed and pressure tested in the bay I will work on the pump and line to the bay. I also need to wire in the SS controller which should go pretty quick.

I am getting closer to getting PI going. Plan is same as before.

- Hellcat Pump

- 6an line to firewall , y adapter, Line A , Line B

- Line A to HPFP

- Line B to JMF fuel rail

- Fuel Rail to FPR

- FPR Return to OEM line for return to basket

Hardest part was getting the coupler on the sleeve but I found that using a socket and a hand socket wrench to push and twist made it really easy.

19mm Socket Worked Better - 6an

This was really just a test to see how much work it would be to get them on but it was not too bad. This site was a big help.

http://anfittingguide.com/install-ptfe-hose-fittings/

My Fuel Pressure Regulator is from my 90 Laser RS which is dead and I ordered new internals so it should work great. I am trying to mount it here if I can. Easy to access and see if there are leaks. Also might try and route the line under the rail to a 180 fitting

I am still waiting on a few fittings. Once I get this all plumbed and pressure tested in the bay I will work on the pump and line to the bay. I also need to wire in the SS controller which should go pretty quick.

Can’t wait for you to hit some power goals man. Super clean build and excited to see what she does with the whole setup running. Keep up the great work bro!PI Update:

I am getting closer to getting PI going. Plan is same as before.

I plan to make a more official how to when I get a chance. I tested out the PTFE line last night and it was not crazy hard just takes time. I would not try and do it without AN vice jaws.

- Hellcat Pump

- 6an line to firewall , y adapter, Line A , Line B

- Line A to HPFP

- Line B to JMF fuel rail

- Fuel Rail to FPR

- FPR Return to OEM line for return to basket

Hardest part was getting the coupler on the sleeve but I found that using a socket and a hand socket wrench to push and twist made it really easy.

19mm Socket Worked Better - 6an

This was really just a test to see how much work it would be to get them on but it was not too bad. This site was a big help.

http://anfittingguide.com/install-ptfe-hose-fittings/

My Fuel Pressure Regulator is from my 90 Laser RS which is dead and I ordered new internals so it should work great. I am trying to mount it here if I can. Easy to access and see if there are leaks. Also might try and route the line under the rail to a 180 fitting

I am still waiting on a few fittings. Once I get this all plumbed and pressure tested in the bay I will work on the pump and line to the bay. I also need to wire in the SS controller which should go pretty quick.

JohnnyTightlips

Motorhead

Thanks man, slowly but surely it will get there.Can’t wait for you to hit some power goals man. Super clean build and excited to see what she does with the whole setup running. Keep up the great work bro!

JohnnyTightlips

Motorhead

Tiny Update:

Well I fiddled a little more last night and made my first line. The fittings are meh and the line leaked. It leaked at the PTFE connection and I know I made it and did it correctly. I also had one of the fittings which seem to have a pin hole leak on it. As this is fuel related I have decided to go with better quality. This was a TT Racing kit from ebay that I was willing to take a shot on but now I will just return.

The line looks good just doesn't work, maybe I can still get scene points.

Well I fiddled a little more last night and made my first line. The fittings are meh and the line leaked. It leaked at the PTFE connection and I know I made it and did it correctly. I also had one of the fittings which seem to have a pin hole leak on it. As this is fuel related I have decided to go with better quality. This was a TT Racing kit from ebay that I was willing to take a shot on but now I will just return.

The line looks good just doesn't work, maybe I can still get scene points.

JohnnyTightlips

Motorhead

Update:

So I was dumb when I tested the ebay lines. I was filling the line with air and putting one end under water. When I noticed air bubbles I thought "oh the line must be leaking" but the air I was seeing was just air trapped in the fitting. When I tested them again last night with constant 120psi air pressure I did not see constant air bubbles. I will still be returning the lines as I already started that process. BUT I would say these are fine and should work without issue as long as you test them. They are cheap and easy to assemble.

After I thought they were no good and leaking I looked for alternative lines. I ended up going with silicone intakes lines. This is what I bought.

3 x Stainless Steel Line 90° Adaptor, -6 AN Black

1 x Stainless Steel Line 180° Adaptor, -6 AN Black

12 x PTFE Braided Stainless Steel Lines, -8 AN Black, per ft.

2 x 8AN brass ring

10 x PTFE Braided Stainless Steel Lines, -6 AN Black, per ft.

2 x 6AN brass ring

2 x Stainless Steel Line 90° Adaptor, -8 AN Black

1 x Stainless Steel Line Straight Adaptor, -8 AN Black

4 x Stainless Steel Line Straight Adaptor, -6 AN Black

1 x Stainless Steel Line 45° Adaptor, -6 AN Black

And here is how they will all connect.

Fuel Pump -> Bulkhead 8an -> 8an 90° ->8an PTFE Line TO ENGINE BAY

8an to 6anA 6anB Y fitting On Firewall near battery

Straight 6anA to HPFP 6an 90° and Vibrant -6AN Male to 5/16 Compression Fitting

6anB to Driver Side Fuel Rail 6an 45°

Passenger Side Fuel Rail 6an 180° to FPR -6AN Flare to 3/8" NPT

Bottom of FPR -6AN Flare to 3/8" NPT to 6an 90° to OEM Return Line -6an 90° and -6AN Male to 5/16 Compression Fitting

I know this is a lot of text but this is also a decent amount of work to walk this all out through my brain.

The new line looks nicer but it is a MOTHER FUCKER to get together.

Here are the steps I take to make this.

I will update with more pictures when it is all together and working.

So I was dumb when I tested the ebay lines. I was filling the line with air and putting one end under water. When I noticed air bubbles I thought "oh the line must be leaking" but the air I was seeing was just air trapped in the fitting. When I tested them again last night with constant 120psi air pressure I did not see constant air bubbles. I will still be returning the lines as I already started that process. BUT I would say these are fine and should work without issue as long as you test them. They are cheap and easy to assemble.

After I thought they were no good and leaking I looked for alternative lines. I ended up going with silicone intakes lines. This is what I bought.

3 x Stainless Steel Line 90° Adaptor, -6 AN Black

1 x Stainless Steel Line 180° Adaptor, -6 AN Black

12 x PTFE Braided Stainless Steel Lines, -8 AN Black, per ft.

2 x 8AN brass ring

10 x PTFE Braided Stainless Steel Lines, -6 AN Black, per ft.

2 x 6AN brass ring

2 x Stainless Steel Line 90° Adaptor, -8 AN Black

1 x Stainless Steel Line Straight Adaptor, -8 AN Black

4 x Stainless Steel Line Straight Adaptor, -6 AN Black

1 x Stainless Steel Line 45° Adaptor, -6 AN Black

And here is how they will all connect.

Fuel Pump -> Bulkhead 8an -> 8an 90° ->8an PTFE Line TO ENGINE BAY

8an to 6anA 6anB Y fitting On Firewall near battery

Straight 6anA to HPFP 6an 90° and Vibrant -6AN Male to 5/16 Compression Fitting

6anB to Driver Side Fuel Rail 6an 45°

Passenger Side Fuel Rail 6an 180° to FPR -6AN Flare to 3/8" NPT

Bottom of FPR -6AN Flare to 3/8" NPT to 6an 90° to OEM Return Line -6an 90° and -6AN Male to 5/16 Compression Fitting

I know this is a lot of text but this is also a decent amount of work to walk this all out through my brain.

The new line looks nicer but it is a MOTHER FUCKER to get together.

Here are the steps I take to make this.

- Put the Line in your Vice with AN Adapter plates

- Slide the collar down the line.

- You might need to use a socket 18mm and have the push and turn at the same time to get it started.

- Once the fitting is far enough on the line start removing the rubber jacket from the stainless braids.

- This part takes FOREVER, best way I have found is have some fresh razor blades, make a slit and try and slide it under the jacket so you can separate it slowly from the braids. The jacket is bonded to the braids which is what takes so long.

- Remove just enough jacket that it is not sticking out when the fitting is seated but need to remove enough to get the brass ferrule "pay attention to the direction of it"

- In the picture above from silicone intakes you can see they barely have any stainless braids left as they must have trimmed it pretty decent. I know their site says you don't need to trim but that is a lie. If you don't trim the braids you will never get the fitting on as the braids just fill the threads.

- It should now look like their next pic

- You can now push and twist the collar up to get it seated against the brass ferrule.

- This part also sucks, you now need to compress the ptfe "as it is sticking out 1/8" using the fitting and twist at the same time to start the threads. I use a combination of vice holdings and swears, good luck

- Once you get the threads started you are good to go and can now twist it until there is about 1/16 gap and it should be all done.

I will update with more pictures when it is all together and working.

Can confirm, assembling siliconintakes lines sucks BIG DICK.

JohnnyTightlips

Motorhead

YEP, they are cheaper though and very well built but you will want to buy extra ferrules for when you fuck it up the first few times.Can confirm, assembling siliconintakes lines sucks BIG DICK.

JohnnyTightlips

Motorhead

Tiny Note:

https://www.harborfreight.com/28-inch-cable-cutters-6649.html

That's what I used to cut the lines, worked well. I then used a punch to push in the line to round it back out. I used a razor blade to trim the top part of the ptfe line if it was not flat.

https://www.harborfreight.com/28-inch-cable-cutters-6649.html

That's what I used to cut the lines, worked well. I then used a punch to push in the line to round it back out. I used a razor blade to trim the top part of the ptfe line if it was not flat.

Ssinstaller

Greenie Member

I used a cutoff wheel to cut the silicone intakes line to length.

I use black heatshrink to finish the ends of the line so I can cut the black sleeve back a little farther from the fitting.

I use black heatshrink to finish the ends of the line so I can cut the black sleeve back a little farther from the fitting.

Last edited:

JohnnyTightlips

Motorhead

That's a good idea, other then cosmetics it doesn't really bother me if a little bare stainless shows. I'd need some pretty big heart shrink as well.I used a cutoff wheel to cut the silicone intakes line to length.

I use black heatshrink to finish the ends of the line so I can cut the black sleeve back a little farther from the fitting.

JohnnyTightlips

Motorhead

Update:

Front driver side of car was clunking pretty bad on hard bumps. I investigated and found that the strut was blown. I contacted Megan and a replacement strut was 135$ which I was planning to do and then eventually update the entire system as it was old and tired anyways. I was then told that the strut was on back order and it would be 3-4 months to get it. I did not want to leave the car on jack stands for that long so I looked into other options.

I decided get the MEGAN EZ Street Coilover Suspension Shock+Spring for Mazda3 MazdaSpeed3 04-09 MR-CDK-M303-EZ and ordered direct from Megan. Due to my situation they gave me a bro deal of $550 with free shipping since they did not have the other part. These are practically identical in every way to what I had they just have 15 way adjustable vs 32 level which I hardly used. The springs and struts are the exact same. The EZ series do not come with camber plates but I was able to transfer the plates from my old set as the bearings were all still in great shape.

New front strut with old camber plate

Fronts are done not sure if I will try and tackle the backs yet or just get the car back on the road. Backs are still in good shape and the hardware I have is exactly the same as what I will be taking off just fresher.

Front driver side of car was clunking pretty bad on hard bumps. I investigated and found that the strut was blown. I contacted Megan and a replacement strut was 135$ which I was planning to do and then eventually update the entire system as it was old and tired anyways. I was then told that the strut was on back order and it would be 3-4 months to get it. I did not want to leave the car on jack stands for that long so I looked into other options.

I decided get the MEGAN EZ Street Coilover Suspension Shock+Spring for Mazda3 MazdaSpeed3 04-09 MR-CDK-M303-EZ and ordered direct from Megan. Due to my situation they gave me a bro deal of $550 with free shipping since they did not have the other part. These are practically identical in every way to what I had they just have 15 way adjustable vs 32 level which I hardly used. The springs and struts are the exact same. The EZ series do not come with camber plates but I was able to transfer the plates from my old set as the bearings were all still in great shape.

New front strut with old camber plate

Fronts are done not sure if I will try and tackle the backs yet or just get the car back on the road. Backs are still in good shape and the hardware I have is exactly the same as what I will be taking off just fresher.

Ssinstaller

Greenie Member

https://www.cabletiesandmore.com/he...MIoo2ciqOv5gIVgZ-zCh3z6QWFEAQYAiABEgIfIvD_BwEThat's a good idea, other then cosmetics it doesn't really bother me if a little bare stainless shows. I'd need some pretty big heart shrink as well.

JohnnyTightlips

Motorhead

Update: "not really"

I don't really have anything to update. Car has been running well even when it is 10f outside. I have been beating on it a little but nothing crazy as I don't have fuel still and it is winter. Still working on getting parts for PI but the last few months have been expensive so that is not a top priority. I have not swapped the rear suspension bits yet as they are the same as the new ones. I helped @deldran part out his red speed as someone ran into him in a parking lot and totaled it. Also worked on my g-pa in laws 2500 diesel and did ball joints. Trucks are a pain in the butt. Everything is HUGE. Next steps for my car will be to finish the PI and tune it. Likely won't be messing with that until some time in march. Will do new plugs and an oil change at the time. Besides the car being a rattle monster I have been very happy with it.

I don't really have anything to update. Car has been running well even when it is 10f outside. I have been beating on it a little but nothing crazy as I don't have fuel still and it is winter. Still working on getting parts for PI but the last few months have been expensive so that is not a top priority. I have not swapped the rear suspension bits yet as they are the same as the new ones. I helped @deldran part out his red speed as someone ran into him in a parking lot and totaled it. Also worked on my g-pa in laws 2500 diesel and did ball joints. Trucks are a pain in the butt. Everything is HUGE. Next steps for my car will be to finish the PI and tune it. Likely won't be messing with that until some time in march. Will do new plugs and an oil change at the time. Besides the car being a rattle monster I have been very happy with it.

JohnnyTightlips

Motorhead

Update:

Well I pulled the trigger on the rest of my PI stuff. Sent it to @Maisonvi as he is going to make a bracket for the pump to sit in the basket.

I am running 8an line to 6an Y at the firewall then so on and so forth, pretty sure I have talked about it like 3 times before in this thread.

I also decided to go back to stock PMM as the vibes have been too much with BSD and DD life and I am SO GLAD I DID. I still have CPE stg 2 rmm and DM TMM but the car is such a pleasure to drive now. Before it was just loud all the time , everything rattled. I had to turn the music to 11 and I felt like I was always driving race car style as it was loud in the cabin at every rpm. Now it is quiet in the cabin and driving is a pleasure, I can actually hear my exhaust and turbo now. I will not be going back unless I decide to take the car to the strip or something. But for DD life this feels like the perfect combo. I think part of the issue was that I have deadening in the car and the NVH leaking in from the PMM were being amplified and stuck in the cabin by my dampening trying to keep music in and noise out. I can use my mirrors again and I can have conversations with my kids. I know it is silly but I feel more relaxed driving it not having so much noise surround me at all times. I know haters gonna hate but this is my life and I am embracing it.

Yes it is ugly, thanks @Maisonvi for hooking me up with a mount as I had given mine to another bro when he was stocking out.

DD Life

Side note:

I drained my catch can and did not know the valve needed to be all the way out for it to be closed. Car ran lean at idle and garbage for a bit until I figured that out. Lesson learned.

Also picked up a new jack, my old one was leaking and I could not bleed it. Works great and reached the oil pan to do the PMM.

Well I pulled the trigger on the rest of my PI stuff. Sent it to @Maisonvi as he is going to make a bracket for the pump to sit in the basket.

I am running 8an line to 6an Y at the firewall then so on and so forth, pretty sure I have talked about it like 3 times before in this thread.

I also decided to go back to stock PMM as the vibes have been too much with BSD and DD life and I am SO GLAD I DID. I still have CPE stg 2 rmm and DM TMM but the car is such a pleasure to drive now. Before it was just loud all the time , everything rattled. I had to turn the music to 11 and I felt like I was always driving race car style as it was loud in the cabin at every rpm. Now it is quiet in the cabin and driving is a pleasure, I can actually hear my exhaust and turbo now. I will not be going back unless I decide to take the car to the strip or something. But for DD life this feels like the perfect combo. I think part of the issue was that I have deadening in the car and the NVH leaking in from the PMM were being amplified and stuck in the cabin by my dampening trying to keep music in and noise out. I can use my mirrors again and I can have conversations with my kids. I know it is silly but I feel more relaxed driving it not having so much noise surround me at all times. I know haters gonna hate but this is my life and I am embracing it.

Yes it is ugly, thanks @Maisonvi for hooking me up with a mount as I had given mine to another bro when he was stocking out.

DD Life

Side note:

I drained my catch can and did not know the valve needed to be all the way out for it to be closed. Car ran lean at idle and garbage for a bit until I figured that out. Lesson learned.

Also picked up a new jack, my old one was leaking and I could not bleed it. Works great and reached the oil pan to do the PMM.

Last edited:

FYI you can rebuild the cylinder in a jack

JohnnyTightlips

Motorhead

Yeah I know but I dicked with it for 2 hours and had no other low profile jacks to work on my car with and was over it. I am not tossing it in the trash so there may be a day where I decide to work on it again.FYI you can rebuild the cylinder in a jack

i mean good luck finding a rebuild kit on short notice, i would probably given up and bought a new one too. i just didnt want you to throw away a jack that needs $10 worth of parts to work again.

Similar threads

- 0.00 star(s)

- Replies

- 1

- Views

- 847

- 0.00 star(s)

- Replies

- 1

- Views

- 729

- 0.00 star(s)

- Replies

- 3

- Views

- 1K

- 0.00 star(s)

- Replies

- 2

- Views

- 1K

- Replies

- 6

- Views

- 567