I would attribute it to the tune pulling timing while coolant temp is below "xx" degrees.

@Realgib3 can probably confirm with my car. But when I was stock block, I could drive the car under 130* coolant temp, but it wouldn't run very well. Just very sluggish.

Now that I'm on a built motor, if I even try to drive anywhere before the coolant temp hits 140*, it's damn near undriveable. 140* is the sweet spot where everything goes into place on my car. I could try pulling down my road while coolant temp is 136* and the car struggles and bucks back and forth, and just drives like crap, but as soon as temp hits 140*, it's like a flip is switched and car drives perfect.

[doublepost=1482959843][/doublepost]

H beams, standard Manley wrist pins, 88mm Manley platinum series pistons (2618), oem bearings (main and rods) , no Keyed crank, and oem head studs.

53k+ miles so far. The first 38k seeing 28-30 psi and 16* up top on a 5862, and the last 15k at 35psi and 18* on the same turbo. Boost curve is progressive to keep torque down. E23 mix in the tank, and spraying 2000cc min of 100% meth.

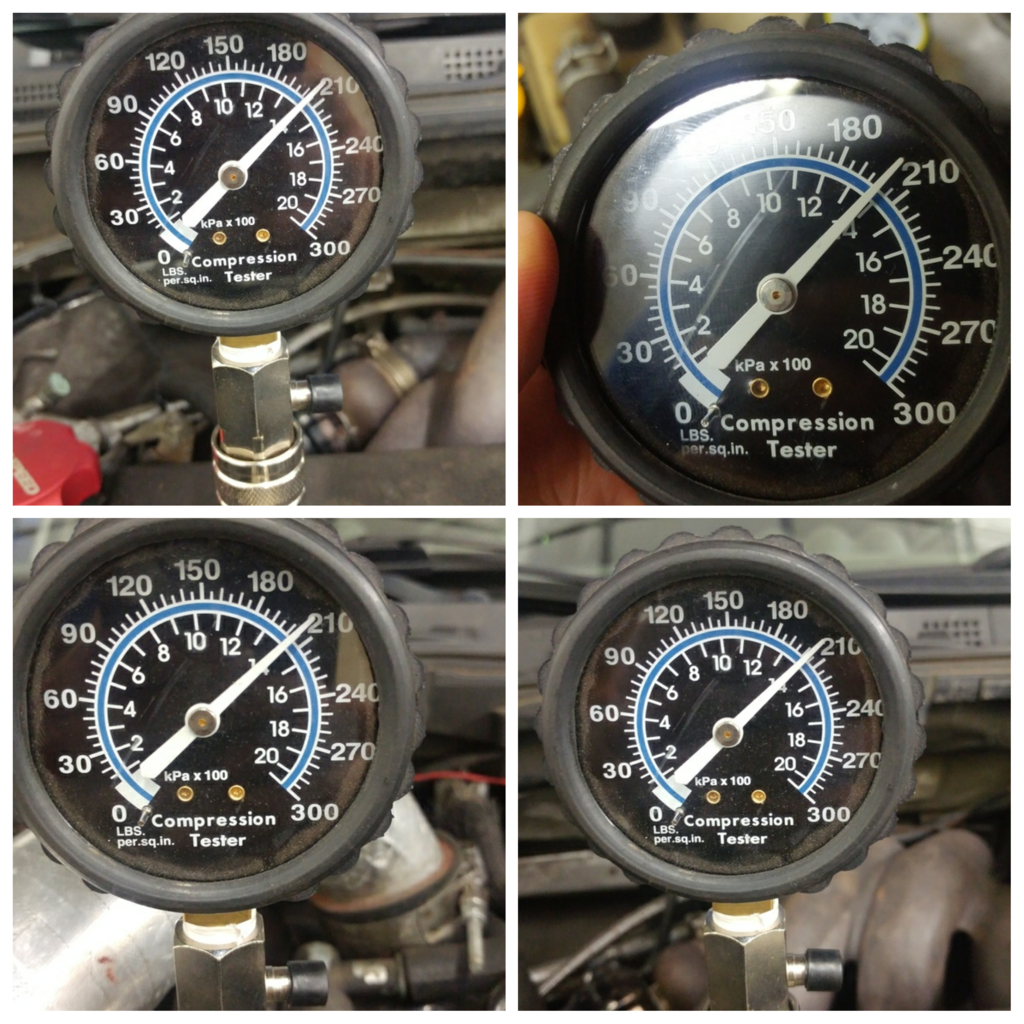

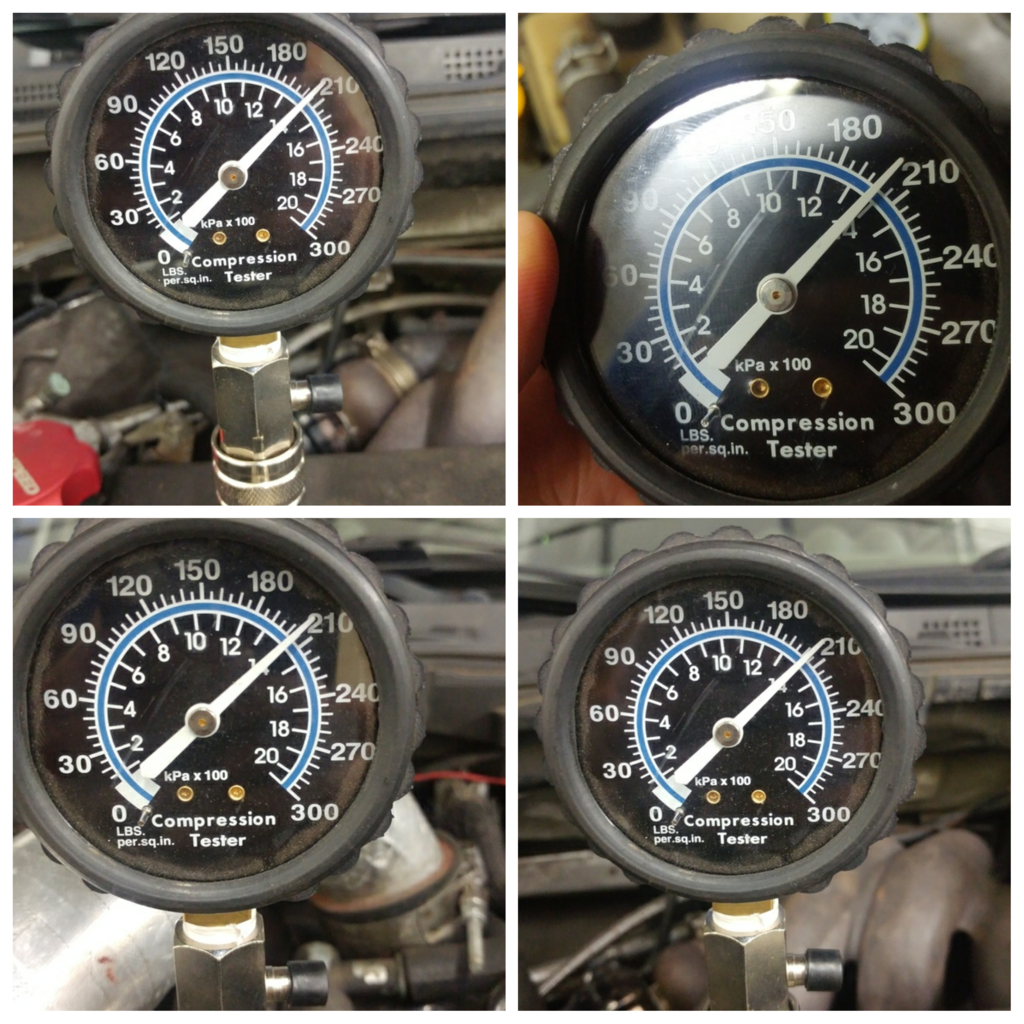

Here's compression test that was done not too long ago