I was going to get more into all this info as I wrote out my build thread... but after reading your post I think there's some important information to pass on to help fill in some gaps...

First off, your current problem sounds like a possible ignition misfire from a bad ignition coil, or spark plug... I'd diagnose this before diving to far into tuning issues...

As for some of your previous struggles with load/boost limits..

For logging, you mentioned knowledge of ForScan... stop using VT to log... go use ForScan.. SOOO MUCH better... It's a little tricky to understand some of the EQ pids and which ones to use, but the logging rate is WAAAAY faster, much more comparable to what you're used to with a stand alone ECU... You can log more pids with out loosing resolution in your logging rates.. This might help you find some of these issues better.. If you are familiar with the scanner diagnostic functions, look up Mode 6 data and the misfire counters.. This will help you to diagnose the current possible misfire issue you've got... You can see individual cylinder misfire data, without a check engine light, or any codes.. You can use that data to narrow down which cylinder has the problem...

Carrying on...

"Load"... All of this load targeting and such... What you are targeting is air mass per intake stroke... You aren't targeting power, or a torque value... This is an air mass calculation.... If you want to go to town mathing your way to a tune, you can google the OBD2 information for Absolute Load... you'll get some formulas with that information.. All of the Fuel tables, and Spark tables will follow the absolute load readings you get from any scanner and what you've got in your tables... This is mandated by federal OBD2 regulations... Your Drive By Wire tables use a different air mass per intake stroke calculation that's more in depth and I can't find any information on it..

I've been told that the OEM coding, doesn't use the boost target table.. No clue what Mazda Edit would call that table, but it's RPM/TPS 0-100%.. with MAP values in it.. From what I understand Cobb is accessing/turning on the OEM development coding, that activates this boost target table as part of their boost targeting strategies.. I don't know what Mazda Edit would do with this table... I don't expect this to be where you were struggling with your previous load limit issues.. But if you choose to modify it, it's important to know that the TPS% value is based off a scanner pid call Relative TPS... this is a calculated TPS value.. The ECU runs a throttle body test every time you shut the car off.. It closes the the throttle blade as far as it can go, and then opens it as far as it can go... The ECU memorizes the TPS voltages at the closed position.. ForScan allows you to see this voltage value... it uses that voltage as the 0% mark for the relative TPS value... The DBW tables (at least 1 of them, you mentioned was labled as Relative TPS)... these values are used for the WG Duty Cycle Table TPS values... If you log Relative TPS and WG Duty cycle, you can map out your WG Duty cycle Table...

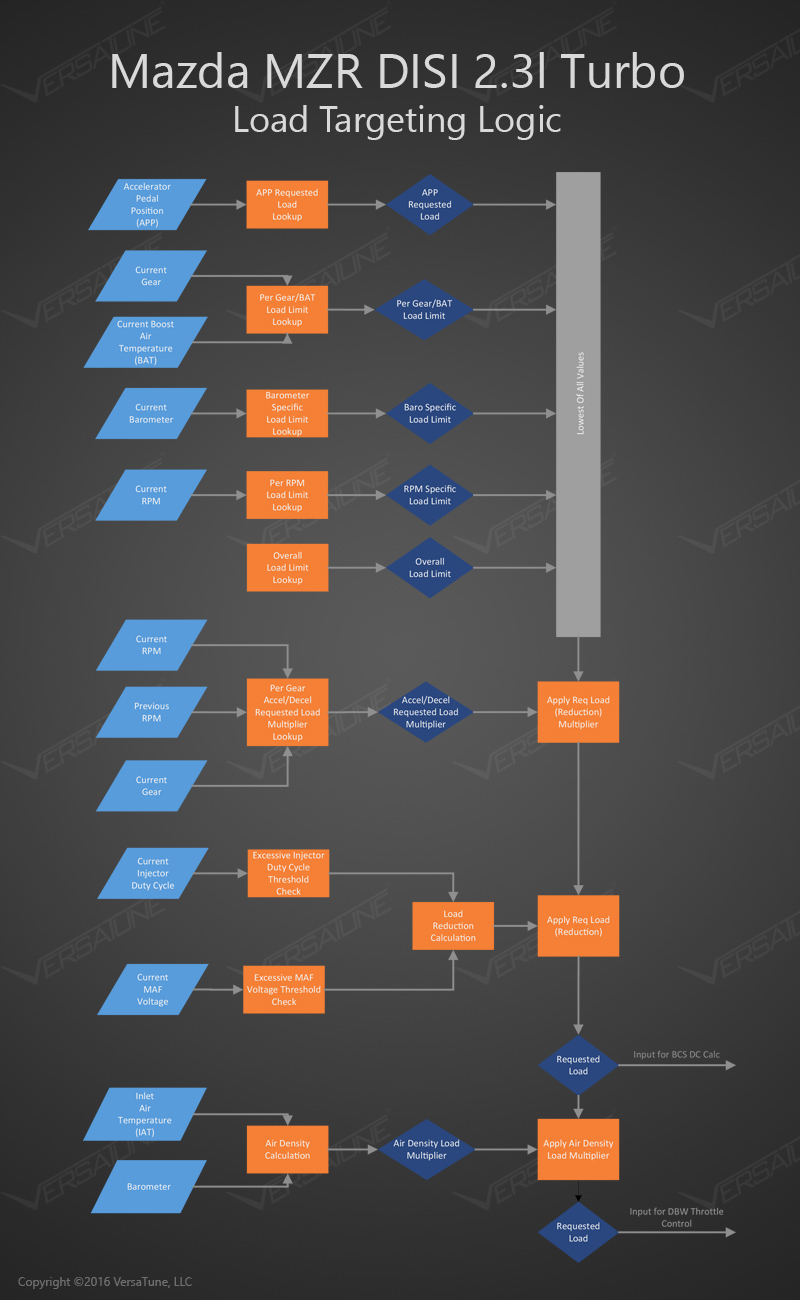

If you are hitting a load limit it'll be due to a couple different reasons... You'll have 3 APP target tables (0-100% and RPM), Both COBB and VT show a 4th APP target table, but I haven't seen it do anything with my tuning adventures.. the ECU attempts to target the lowest of these values anytime you aren't under WOT conditions... The load target per gear tables are used under WOT conditions... All of these tables you can over shoot your targets.. You're WG and Load compensation tables are used to try and keep you with in these targets.. You could be limited in this area...

You'll have 2 RPM based MAX LOAD tables (VT calls them Operating Load limits, COBB calls them Calc Load MAX)... these tables, set the max fueling calculation limits.. If you use ForScan for logging and you watch the Calculated Load pid.. You'll see this value change if you change these Operating Load Limit Tables... There's 1 more RPM based MAX LOAD table and a single value max load.. (VT calls it Requested Load Limit RPM, Requested Load Limit Overall.. COBB calls them Throttle Requested Load A/B)... These tables work the same as the Operating Load limit tables, but work on the DBW load calculations.. Then you have a BARO/RPM requested Load limit table.. These tables define max limits.. the ECU takes more extreme measures such as slowly cutting fuel in order to stay with in these limits... So you could be limited in that area.. especially if you find you've been adding fuel to your MAF cal in this area...

There's an RPM based soft boost limit table... VT calls it overboost protection throttle reduction, Cobb calls it Boost Threshold for Baro Multiplier... This table works in conjunction with a BARO/RPM Multiplier table.. VT calls this table boost limit baro adjustment.. It's show as values in % form... Cobb calls the table WG Duty baro multiplier.. They list it as a number value 1.0 - 0.5.. How it works is simple.. Stock value at 5500 RPM is 29.2 psi (this is an absolute MAP value from VT).. Cobb takes the absolute map and converts it to a gauge map value.. I don't like this.. it creates more work, if you're going to do any math work to develop your tune.. You should be tuning/logging in absolute map values... side note over... on the BARO/RPM table at 13.56psi and 5500RPM the value is 86.6%.... You take 29.2psi and multiply it by 86.6%... This equals 25.29psi... So if you've got a BARO reading 13.56psi, your map limit is 25.29psi (11.73 PSI boost pressure)... Stock values run 100% above 13.56 baro... So that means you'd be running at 29.2psi (14.49 boost pressure at 14.71 baro)... This is a soft limit... It'll lower throttle, reduce wastegate DC to stay in this range... This is where I suspect you are hitting your limit...

I mentioned Absolute MAP readings because all OEM pressure referenced values are based off Absolute MAP... If you log in absolute map, all you need to do is either log BARO, subtract that from your absolute map reading to get boost pressure... Or simply look up the baro conditions on a weather app for your location when you are logging and subtract your absolute map value by that to get your boost pressure... You should never waste a data pid logging "boost pressure" If you don't get to select looking at the tune in imperial or metric values.. Chances are the OEM tune is based in Metric values... which means it'll be in kpa, not psi like I've mentioned..

You asked about Open Loop functions... There's actually 3 states the ECU can run in... Closed Loop, Open Loop and something called Open Loop Drive.... Closed Loop and Open Loop Drive are the 2 most common states.. Open Loop is a transitional state, used during things like warm up enrichment, or going from decel fuel cut, back to closed or open loop drive... The ECU has 2 strategies for switching out of closed loop and into Open Loop Drive... Load based, and APP position based.... You've got RPM based Cloosed loop tables with load values in them... when the car exceeds those load values it engages the closed loop counter.. You need to stay above the load value long enough for the counter to count down before it'll switch into Open Loop Drive.. This counter isn't something you'll see in any scan data, it's not a traditional time value either... There's also RPM based APP threshold tables.. 5 of them... These define the APP position % to trigger WOT conditions... Stock tune has some of these tables with values above 100%... This means there are times when the stock tune will never trigger a WOT condition... If you set all of these tables about 100% you'll never trigger any of the WOT fuel tables, or other WOT related command tables... If you set this to lets say 5%... you'll be running on all your WOT tables above 5% APP...

COBB and Versatuner show 3 closed loop max tables... This is supposed to be for fuel trimming function during WOT conditions... I've read this is a Gen2 ecu function that COBB and Versatuner have implemented into Gen1 coding... It doesn't appear to work on my Speed6...