Salvaged from the old forum user DynoBunny's post using WebArchive. This helped me, it will help you!

Note: A lot of these steps could be skipped depending on what you’re replacing and how you like to work. I’m not in a rush when I work on my car so I was thorough and clean.

Here’s the parts:

1/2023 update! You can also buy the whole unit!

A601-17-470 Case assembly (with boot)

A601-17-530 Air breather

ms3_pivot_shaft_seal_replacment-001

ms3_pivot_shaft_seal_replacment-001

Here’s the tools I used in case you want to have them ready:

(You don’t need them all but I like to make things easy)

ms3_pivot_shaft_seal_replacment-063

ms3_pivot_shaft_seal_replacment-063

I jacked the car up, I’m tall:

ms3_pivot_shaft_seal_replacment-002

ms3_pivot_shaft_seal_replacment-002

Remove whatever intake you have:

ms3_pivot_shaft_seal_replacment-003

ms3_pivot_shaft_seal_replacment-003

Pop off the shift linkage. I used two small flat heads on either side.

ms3_pivot_shaft_seal_replacment-004

ms3_pivot_shaft_seal_replacment-004

Take out the two 12mm bolts holding the shift mechanism on:

ms3_pivot_shaft_seal_replacment-005

ms3_pivot_shaft_seal_replacment-005

The shorter bolt goes in the back:

ms3_pivot_shaft_seal_replacment-006

ms3_pivot_shaft_seal_replacment-006

I think this is the clip some people were referencing that could slide off into the trans. Since you take this part off before you take the pivot shaft out, just make sure it’s accounted for:

ms3_pivot_shaft_seal_replacment-056

ms3_pivot_shaft_seal_replacment-056

Next take out the other three 12mm bolts that hold the shaft in:

ms3_pivot_shaft_seal_replacment-007

ms3_pivot_shaft_seal_replacment-007

ms3_pivot_shaft_seal_replacment-008

ms3_pivot_shaft_seal_replacment-008

This 14mm bolt is has the guide pin for the shaft so it needs to come out to pull the assembly out:

ms3_pivot_shaft_seal_replacment-009

ms3_pivot_shaft_seal_replacment-009

This is self explanatory. I used a chisel, just stick it in the top and pull to the side. Works every time for me, and I feel safer than beating and prying on it:

ms3_pivot_shaft_seal_replacment-010

ms3_pivot_shaft_seal_replacment-010

The inside, keep in mind you’ll need to fit the pivot shaft into that bearing in the bottom. It’s easy to get back in if you realize what you’re doing:

ms3_pivot_shaft_seal_replacment-011

ms3_pivot_shaft_seal_replacment-011

Don’t get anything in there, you’ll need to clean that surface sometime before the final assembly. I use a razor and drag it away from the blade. Also put a rag in there to catch any accidental drops:

ms3_pivot_shaft_seal_replacment-012

ms3_pivot_shaft_seal_replacment-012

ms3_pivot_shaft_seal_replacment-039

ms3_pivot_shaft_seal_replacment-039

Pull the assembly up and out, you’ll need to tip it forward a bit to get past the intake mount. Lay it down on something clean:

ms3_pivot_shaft_seal_replacment-013

ms3_pivot_shaft_seal_replacment-013

See how the guide pin works:

ms3_pivot_shaft_seal_replacment-015

ms3_pivot_shaft_seal_replacment-015

This pin has to come out. There’s two sides; one’s beveled, the other isn’t. This is the side it will go back in:

ms3_pivot_shaft_seal_replacment-016

ms3_pivot_shaft_seal_replacment-016

This is the side you’ll tap it out from. I used a 5/32 punch:

ms3_pivot_shaft_seal_replacment-017

ms3_pivot_shaft_seal_replacment-017

ms3_pivot_shaft_seal_replacment-018

ms3_pivot_shaft_seal_replacment-018

Whenever I take things apart I mark them with a paint marker, good habit. Although this only goes one way, so you don't need to, but it’s still handy:

ms3_pivot_shaft_seal_replacment-019

ms3_pivot_shaft_seal_replacment-019

Slide the piece off the shaft and then remove the boot from the plate:

ms3_pivot_shaft_seal_replacment-020

ms3_pivot_shaft_seal_replacment-020

ms3_pivot_shaft_seal_replacment-021

ms3_pivot_shaft_seal_replacment-021

This is the piece that has all the parts you’ll replace. Here is the seal:

ms3_pivot_shaft_seal_replacment-022

ms3_pivot_shaft_seal_replacment-022

The bearing:

ms3_pivot_shaft_seal_replacment-023

ms3_pivot_shaft_seal_replacment-023

The seal came out really easy, I used my finger. If you need to get a screwdriver, just don’t maul the wall inside:

ms3_pivot_shaft_seal_replacment-024

ms3_pivot_shaft_seal_replacment-024

I put it on two 2x4s and used a 19mm deep socket with a hammer to tap the bearing out. Also used a pair of vice grips to hold the socket, I don’t have the best aim with a hammer and it’s easier to hold. Always use safety glasses when hammering:

ms3_pivot_shaft_seal_replacment-025

ms3_pivot_shaft_seal_replacment-025

ms3_pivot_shaft_seal_replacment-026

ms3_pivot_shaft_seal_replacment-026

ms3_pivot_shaft_seal_replacment-027

ms3_pivot_shaft_seal_replacment-027

Make sure everything is very clean when you put the new bearing in. I applied some synthetic grease (mobil1) to the bearing to help it slide in. If you have a bearing press, great use it. If not a clean cloth, wooden board, and hammer will work just as good. Just take it slow, tap it in a little and make sure it’s straight. Once it’s in as far as you can get it with the wooden board, use the 19mm to go the rest of the way:

ms3_pivot_shaft_seal_replacment-028

ms3_pivot_shaft_seal_replacment-028

ms3_pivot_shaft_seal_replacment-029

ms3_pivot_shaft_seal_replacment-029

Turn it over and make sure you’re in all the way to the lip. Don’t beat it in too hard or you’ll damage it:

ms3_pivot_shaft_seal_replacment-030

ms3_pivot_shaft_seal_replacment-030

The seal goes in this way. I didn’t need to hit it in, just pushed it in evenly with my fingers. Again don’t push it in too far, just past the edge:

ms3_pivot_shaft_seal_replacment-031

ms3_pivot_shaft_seal_replacment-031

ms3_pivot_shaft_seal_replacment-032

ms3_pivot_shaft_seal_replacment-032

I used that same 5/32 punch turned around to get the breather out:

ms3_pivot_shaft_seal_replacment-033

ms3_pivot_shaft_seal_replacment-033

ms3_pivot_shaft_seal_replacment-034

ms3_pivot_shaft_seal_replacment-034

A 13mm deep will go over the vent but catch the lip to hammer it back in:

ms3_pivot_shaft_seal_replacment-036

ms3_pivot_shaft_seal_replacment-036

ms3_pivot_shaft_seal_replacment-037

ms3_pivot_shaft_seal_replacment-037

ms3_pivot_shaft_seal_replacment-038

ms3_pivot_shaft_seal_replacment-038

Slide the cover back onto the shaft and attach the boot:

ms3_pivot_shaft_seal_replacment-040

ms3_pivot_shaft_seal_replacment-040

ms3_pivot_shaft_seal_replacment-041

ms3_pivot_shaft_seal_replacment-041

If this piece came apart, it’s no big deal, it just slides over it:

ms3_pivot_shaft_seal_replacment-042

ms3_pivot_shaft_seal_replacment-042

ms3_pivot_shaft_seal_replacment-043

ms3_pivot_shaft_seal_replacment-043

You can see how this only goes two ways, but if you do it the wrong way the pin hole won’t line up:

ms3_pivot_shaft_seal_replacment-044

ms3_pivot_shaft_seal_replacment-044

ms3_pivot_shaft_seal_replacment-047

ms3_pivot_shaft_seal_replacment-047

ms3_pivot_shaft_seal_replacment-048

ms3_pivot_shaft_seal_replacment-048

When you put the pin back, hammer it in from the beveled side. Also the pin should have a slight taper. Put the smaller end in first. It should be just flush with the back side:

ms3_pivot_shaft_seal_replacment-049

ms3_pivot_shaft_seal_replacment-049

ms3_pivot_shaft_seal_replacment-050

ms3_pivot_shaft_seal_replacment-050

ms3_pivot_shaft_seal_replacment-051

ms3_pivot_shaft_seal_replacment-051

ms3_pivot_shaft_seal_replacment-052

ms3_pivot_shaft_seal_replacment-052

I used Permatex gasket maker. It’s made to resist gear oil, specifically the additives for LSDs. Whether this is bullshit, idk. Be aware that this stuff takes 24hr to cure, you may want to opt for a different kind if you can’t be down that long:

ms3_pivot_shaft_seal_replacment-053

ms3_pivot_shaft_seal_replacment-053

ms3_pivot_shaft_seal_replacment-062

ms3_pivot_shaft_seal_replacment-062

Make a small bead around. I go around the bolt holes as well. Keep the stuff to the outside edge since it’ll squish in:

ms3_pivot_shaft_seal_replacment-054

ms3_pivot_shaft_seal_replacment-054

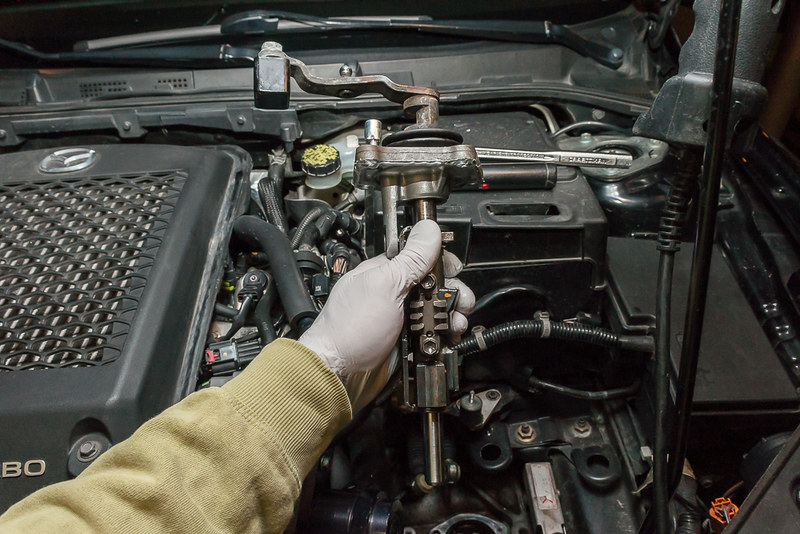

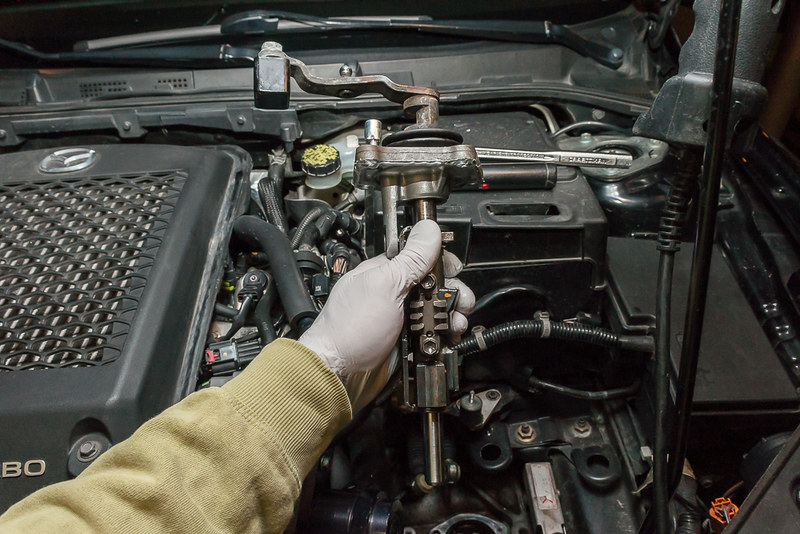

Here’s the big deal, put this mother fucker back in. This is how it should look when you’re ready. Make sure there’s NOTHING down in the hole. Be careful, don’t hit the sealant on anything. Remember you’ll need to have a slight angle to get it past that intake mount. There’s also that hole that you’ll need to line the shaft up in; it’s directly centered. If it gets to the bottom and won’t go the last inch, turn the shift mechanism a little back and forth and it will go. Be patient, be cool, you’ll get it in:

ms3_pivot_shaft_seal_replacment-055

ms3_pivot_shaft_seal_replacment-055

Once it’s in put those three 12mm bolts back, but don’t tighten them down yet:

ms3_pivot_shaft_seal_replacment-057

ms3_pivot_shaft_seal_replacment-057

Put the 14mm bolt in:

ms3_pivot_shaft_seal_replacment-058

ms3_pivot_shaft_seal_replacment-058

Put the other piece of the shift mechanism in. See how it goes:

ms3_pivot_shaft_seal_replacment-059

ms3_pivot_shaft_seal_replacment-059

Put the other two 12mm bolts in and tighten the four main ones in a criss cross pattern. I don’t have the torque specs but I did them around 15-20 ft/lbs:

ms3_pivot_shaft_seal_replacment-060

ms3_pivot_shaft_seal_replacment-060

That’s it!

Note: A lot of these steps could be skipped depending on what you’re replacing and how you like to work. I’m not in a rush when I work on my car so I was thorough and clean.

Here’s the parts:

1/2023 update! You can also buy the whole unit!

A601-17-470 Case assembly (with boot)

A601-17-530 Air breather

ms3_pivot_shaft_seal_replacment-001

ms3_pivot_shaft_seal_replacment-001Here’s the tools I used in case you want to have them ready:

(You don’t need them all but I like to make things easy)

ms3_pivot_shaft_seal_replacment-063

ms3_pivot_shaft_seal_replacment-063I jacked the car up, I’m tall:

ms3_pivot_shaft_seal_replacment-002

ms3_pivot_shaft_seal_replacment-002Remove whatever intake you have:

ms3_pivot_shaft_seal_replacment-003

ms3_pivot_shaft_seal_replacment-003Pop off the shift linkage. I used two small flat heads on either side.

ms3_pivot_shaft_seal_replacment-004

ms3_pivot_shaft_seal_replacment-004Take out the two 12mm bolts holding the shift mechanism on:

ms3_pivot_shaft_seal_replacment-005

ms3_pivot_shaft_seal_replacment-005The shorter bolt goes in the back:

ms3_pivot_shaft_seal_replacment-006

ms3_pivot_shaft_seal_replacment-006I think this is the clip some people were referencing that could slide off into the trans. Since you take this part off before you take the pivot shaft out, just make sure it’s accounted for:

ms3_pivot_shaft_seal_replacment-056

ms3_pivot_shaft_seal_replacment-056Next take out the other three 12mm bolts that hold the shaft in:

ms3_pivot_shaft_seal_replacment-007

ms3_pivot_shaft_seal_replacment-007 ms3_pivot_shaft_seal_replacment-008

ms3_pivot_shaft_seal_replacment-008This 14mm bolt is has the guide pin for the shaft so it needs to come out to pull the assembly out:

ms3_pivot_shaft_seal_replacment-009

ms3_pivot_shaft_seal_replacment-009This is self explanatory. I used a chisel, just stick it in the top and pull to the side. Works every time for me, and I feel safer than beating and prying on it:

ms3_pivot_shaft_seal_replacment-010

ms3_pivot_shaft_seal_replacment-010The inside, keep in mind you’ll need to fit the pivot shaft into that bearing in the bottom. It’s easy to get back in if you realize what you’re doing:

ms3_pivot_shaft_seal_replacment-011

ms3_pivot_shaft_seal_replacment-011Don’t get anything in there, you’ll need to clean that surface sometime before the final assembly. I use a razor and drag it away from the blade. Also put a rag in there to catch any accidental drops:

ms3_pivot_shaft_seal_replacment-012

ms3_pivot_shaft_seal_replacment-012 ms3_pivot_shaft_seal_replacment-039

ms3_pivot_shaft_seal_replacment-039Pull the assembly up and out, you’ll need to tip it forward a bit to get past the intake mount. Lay it down on something clean:

ms3_pivot_shaft_seal_replacment-013

ms3_pivot_shaft_seal_replacment-013See how the guide pin works:

ms3_pivot_shaft_seal_replacment-015

ms3_pivot_shaft_seal_replacment-015This pin has to come out. There’s two sides; one’s beveled, the other isn’t. This is the side it will go back in:

ms3_pivot_shaft_seal_replacment-016

ms3_pivot_shaft_seal_replacment-016This is the side you’ll tap it out from. I used a 5/32 punch:

ms3_pivot_shaft_seal_replacment-017

ms3_pivot_shaft_seal_replacment-017 ms3_pivot_shaft_seal_replacment-018

ms3_pivot_shaft_seal_replacment-018Whenever I take things apart I mark them with a paint marker, good habit. Although this only goes one way, so you don't need to, but it’s still handy:

ms3_pivot_shaft_seal_replacment-019

ms3_pivot_shaft_seal_replacment-019Slide the piece off the shaft and then remove the boot from the plate:

ms3_pivot_shaft_seal_replacment-020

ms3_pivot_shaft_seal_replacment-020 ms3_pivot_shaft_seal_replacment-021

ms3_pivot_shaft_seal_replacment-021This is the piece that has all the parts you’ll replace. Here is the seal:

ms3_pivot_shaft_seal_replacment-022

ms3_pivot_shaft_seal_replacment-022The bearing:

ms3_pivot_shaft_seal_replacment-023

ms3_pivot_shaft_seal_replacment-023The seal came out really easy, I used my finger. If you need to get a screwdriver, just don’t maul the wall inside:

ms3_pivot_shaft_seal_replacment-024

ms3_pivot_shaft_seal_replacment-024I put it on two 2x4s and used a 19mm deep socket with a hammer to tap the bearing out. Also used a pair of vice grips to hold the socket, I don’t have the best aim with a hammer and it’s easier to hold. Always use safety glasses when hammering:

ms3_pivot_shaft_seal_replacment-025

ms3_pivot_shaft_seal_replacment-025 ms3_pivot_shaft_seal_replacment-026

ms3_pivot_shaft_seal_replacment-026 ms3_pivot_shaft_seal_replacment-027

ms3_pivot_shaft_seal_replacment-027Make sure everything is very clean when you put the new bearing in. I applied some synthetic grease (mobil1) to the bearing to help it slide in. If you have a bearing press, great use it. If not a clean cloth, wooden board, and hammer will work just as good. Just take it slow, tap it in a little and make sure it’s straight. Once it’s in as far as you can get it with the wooden board, use the 19mm to go the rest of the way:

ms3_pivot_shaft_seal_replacment-028

ms3_pivot_shaft_seal_replacment-028 ms3_pivot_shaft_seal_replacment-029

ms3_pivot_shaft_seal_replacment-029Turn it over and make sure you’re in all the way to the lip. Don’t beat it in too hard or you’ll damage it:

ms3_pivot_shaft_seal_replacment-030

ms3_pivot_shaft_seal_replacment-030The seal goes in this way. I didn’t need to hit it in, just pushed it in evenly with my fingers. Again don’t push it in too far, just past the edge:

ms3_pivot_shaft_seal_replacment-031

ms3_pivot_shaft_seal_replacment-031 ms3_pivot_shaft_seal_replacment-032

ms3_pivot_shaft_seal_replacment-032I used that same 5/32 punch turned around to get the breather out:

ms3_pivot_shaft_seal_replacment-033

ms3_pivot_shaft_seal_replacment-033 ms3_pivot_shaft_seal_replacment-034

ms3_pivot_shaft_seal_replacment-034A 13mm deep will go over the vent but catch the lip to hammer it back in:

ms3_pivot_shaft_seal_replacment-036

ms3_pivot_shaft_seal_replacment-036 ms3_pivot_shaft_seal_replacment-037

ms3_pivot_shaft_seal_replacment-037 ms3_pivot_shaft_seal_replacment-038

ms3_pivot_shaft_seal_replacment-038Slide the cover back onto the shaft and attach the boot:

ms3_pivot_shaft_seal_replacment-040

ms3_pivot_shaft_seal_replacment-040 ms3_pivot_shaft_seal_replacment-041

ms3_pivot_shaft_seal_replacment-041If this piece came apart, it’s no big deal, it just slides over it:

ms3_pivot_shaft_seal_replacment-042

ms3_pivot_shaft_seal_replacment-042 ms3_pivot_shaft_seal_replacment-043

ms3_pivot_shaft_seal_replacment-043You can see how this only goes two ways, but if you do it the wrong way the pin hole won’t line up:

ms3_pivot_shaft_seal_replacment-044

ms3_pivot_shaft_seal_replacment-044 ms3_pivot_shaft_seal_replacment-047

ms3_pivot_shaft_seal_replacment-047 ms3_pivot_shaft_seal_replacment-048

ms3_pivot_shaft_seal_replacment-048When you put the pin back, hammer it in from the beveled side. Also the pin should have a slight taper. Put the smaller end in first. It should be just flush with the back side:

ms3_pivot_shaft_seal_replacment-049

ms3_pivot_shaft_seal_replacment-049 ms3_pivot_shaft_seal_replacment-050

ms3_pivot_shaft_seal_replacment-050 ms3_pivot_shaft_seal_replacment-051

ms3_pivot_shaft_seal_replacment-051 ms3_pivot_shaft_seal_replacment-052

ms3_pivot_shaft_seal_replacment-052I used Permatex gasket maker. It’s made to resist gear oil, specifically the additives for LSDs. Whether this is bullshit, idk. Be aware that this stuff takes 24hr to cure, you may want to opt for a different kind if you can’t be down that long:

ms3_pivot_shaft_seal_replacment-053

ms3_pivot_shaft_seal_replacment-053 ms3_pivot_shaft_seal_replacment-062

ms3_pivot_shaft_seal_replacment-062Make a small bead around. I go around the bolt holes as well. Keep the stuff to the outside edge since it’ll squish in:

ms3_pivot_shaft_seal_replacment-054

ms3_pivot_shaft_seal_replacment-054Here’s the big deal, put this mother fucker back in. This is how it should look when you’re ready. Make sure there’s NOTHING down in the hole. Be careful, don’t hit the sealant on anything. Remember you’ll need to have a slight angle to get it past that intake mount. There’s also that hole that you’ll need to line the shaft up in; it’s directly centered. If it gets to the bottom and won’t go the last inch, turn the shift mechanism a little back and forth and it will go. Be patient, be cool, you’ll get it in:

ms3_pivot_shaft_seal_replacment-055

ms3_pivot_shaft_seal_replacment-055Once it’s in put those three 12mm bolts back, but don’t tighten them down yet:

ms3_pivot_shaft_seal_replacment-057

ms3_pivot_shaft_seal_replacment-057Put the 14mm bolt in:

ms3_pivot_shaft_seal_replacment-058

ms3_pivot_shaft_seal_replacment-058Put the other piece of the shift mechanism in. See how it goes:

ms3_pivot_shaft_seal_replacment-059

ms3_pivot_shaft_seal_replacment-059Put the other two 12mm bolts in and tighten the four main ones in a criss cross pattern. I don’t have the torque specs but I did them around 15-20 ft/lbs:

ms3_pivot_shaft_seal_replacment-060

ms3_pivot_shaft_seal_replacment-060That’s it!

Last edited: